FüSiC

Table of contents

FüSiC: Characteristic pressure-assisted and process-assured joining and sealing of SiC-Components and Containments

| Project manager: |

Prof. Dr.-Ing. habil. Wolfgang Lippmann |

| Contributor: |

Dipl.-Ing. Marius Lau |

| Duration: | 01.01.2018 – 30.06.2020 |

| Funding: | BMBF – Bundesministerium für Bildung und Forschung |

| Funding code: |

13XP5045D |

| Cooperations: |

|

| Joint project coordination: | FCT Ingenieurkeramik GmbH, Dr.-Ing. Ulrich Degenhardt |

Brief Description

The aim of the two-year project is the development of characteristic joining methods for the mechanically strong, corrosion-resistant and gas-tight joining and sealing of silicon carbide components and containers.

At the Chair of Hydrogen and Nuclear Technology of the TU Dresden, investigations and evaluations of silicon carbide joining compounds will be carried out in order to characterize the bonding state and the sintering progress in the joining zone.

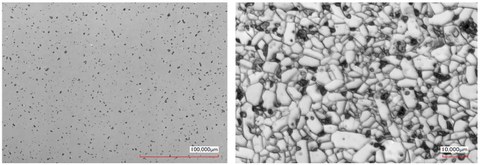

For this purpose, the structure of the ceramic in the joining zone and in the base material is examined qualitatively and quantitatively to show structure-property relationships. It is essential for the ceramics to determine the porosity and the grain size by image analysis. For the measurement of the porosity, the ceramics are prepared ceramographically and imaged in a polished state by a microscope. In the grain size analysis, the polished sample is additionally contrasted so that the grain boundaries become visible. Both states are presented in the figure 1, with the polished microsection on the left and the contrasted on the right.

Figure 1: Light micrographs of silicon carbide left in the polished state and right in the contrasted state.

In parallel with the experimental investigations, a FEM model for the joining process will be set up to determine process and geometry parameters that are not critical with respect to the thermo-mechanical stress states.