Labs and Equipment

Powder metallurgy lab

In the powder metallurgy lab powder processing, powder characterisation and shaping of parts is perfomed. After that heat treatments can be performed in the heat treatment lab. Thus accept for the powder production every part of the process chain of powder metallurgy is represented at the chair.

Head

© Cornelia Müller

© Cornelia Müller

wissenschaftlicher Mitarbeiter

NameMr Dipl.-Ing. Christoph Höhnel

Send encrypted email via the SecureMail portal (for TUD external users only).

Equipment

- hydraulic press

- warm and cold pressing is possible

- max. force: 600 kN

- cold isostatic press (CIP)

- max. pressure: 250 MPa

- usable space: d = 100 x 550 mm

- planetary ball mill

- shaking mill

- turbula mixer

- vibrational sieve machine

- inert gas box (argon)

- laser diffraction partical size analyzer

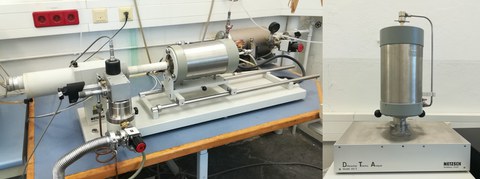

Thermoanalytical lab

In this lab dilatometer and differantial thermal analysis measurements are performed. The maximal temperature samples can be tested at 2000 °C. Measurements can be performed under different atmospheres.

Head

© Cornelia Müller

© Cornelia Müller

wissenschaftlicher Mitarbeiter

NameMr Dipl.-Ing. Christoph Höhnel

Send encrypted email via the SecureMail portal (for TUD external users only).

Equipment

- high temperature dilatometer

- Tmax: 2000 °C; N2, Ar, vacuum up to 10-5 mbar

- Tmax: 1600 °C; H2; N2, Ar, vacuum up to 10-2 mbar

- Tmax: 1400 °C; H2, N2, Ar; vacuum up to 10-4 mbar

- Differential Thermal Analysis (DTA)

- Tmax: 1450 °C, H2, N2, Ar, vacuum up to 10-2 mbar, air

Heat treatment/sintering lab

In the heat treatment lab samples produced in-house or from outside can be heat treated. This can happen with different atmospheres at temperatures up to 1500 °C. Possible heat treatments are the debinding and sintering of green bodies, homogenizing, stress relieving, coarse grain tempering, recristallisation and more.

Head

Techniker

NameMr Dipl.-Ing. (FH) Uwe Gutsche

Send encrypted email via the SecureMail portal (for TUD external users only).

Equipment

all furnaces are equiped with data trecking (temperature-time-curve)

- inert gas tube furnaces

- electronic temperatur control

- usable space: d = 60 mm bzw. 100 mm, l = 260 mm

- max. mass of the parts: 1 kg or 2 kg

- Tmax: 1300 °C

- atmospheres: H2, N2, Ar

- high temperatur high vacuum furnace

- electronic temperatur control

- usable space: d = 85 x 200 mm

- Tmax : 1500 °C

- pressure: 10-5 mbar

- vacuum quench furnace

- electronic temperatur control

- usable space: d = 50 x 100 mm

-

Tmax : 1500 °C

-

pressure: 10-5 mbar

- salt bath hardening

- usable space: d = 350 mm, h = 400 mm

- max. mass of parts: 15 kg

- Tmax : 900 °C and 550 °C

- only for iron alloys

- chamber furnace (27 liters)

- usable space: h = 200 mm, w = 300 mm, d = 450 mm

- Tmax: 1300 °C

- chamber furnaces (3 liters)

- partly with electronic temperatur control

- usable space: h = 90 mm, w = 140 mm, d = 240 mm

- max. mass of the parts: 5 kg

- Tmax : 1300 °C

- drying chambers

- partly with electronic temperatur control

- max. mass of ther parts: 10 kg

- Tmax : 500 °C, optionally with circulating air

- air circulation furnace

- with electronic temperatur control

- usable space: d = 290 mm, h = 500 mm

- max. mass of the parts: 15 kg

- Tmax : 600 °C

- convection furnace

- with electronic temperatur control

- usable space: h = 300 mm, w = 300 mm, d = 450 mm

- Tmax : 850 °C