Nov 13, 2018

Dresden composite impeller wins prestigious AVK award

In initial load tests, the lightweight radial impeller was able to achieve better performance values than a comparable metal impeller.

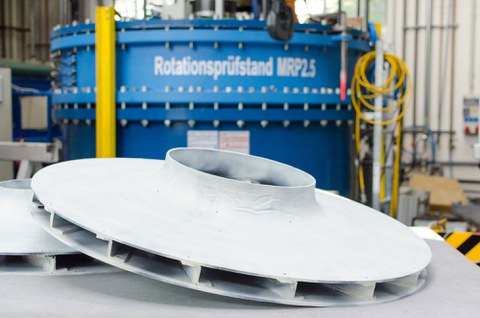

At the International Composites Congress 2018 in Stuttgart, the project team led by Prof. Maik Gude was awarded an AVK Prize in the "Research/Science" category for a radial impeller in modular metal-fibre composite design developed at the Institute for Lightweight Engineering and Polymer Technology (ILK) at the TU Dresden together with the Research Association for Air and Drying Technology (FLT). In initial load tests, the impeller was able to achieve better performance values than a comparable metal impeller. In the centrifugal tests carried out at the ILK, a circumferential speed of 543 m/s was achieved at a maximum speed of 10,266 1/min. This is nearly equivalent to a doubling of the maximum speed compared to the reference part.

Fiber-reinforced composites especially suitable

ILK wins AVK Award for high-performance composite radial impeller. from left to right: Dr.-Ing. Rudolf Kleinholz (Chairman of the AVK Innovation Award Jury), Dipl.-Ing. Martin Pohl (ILK), Dr.-Ing. Peter Hermerath (FLT), Prof. Dr.-Ing. Jens Ridzewski (AVK)

Radial impellers in industrial blowers are used to transport process gases in chemical plants, for example. They are subject to high mechanical, thermal and medial stresses. The purely metallic designs used up to now have been largely exhausted in terms of increased performance.

In the FLT funding project "Lightweighting of radial impellers" (LeRala), the team has developed a radial impeller in modular metal-fibre composite design. This showed that fibre composite materials are highly suitable for use in radial impellers due to their outstanding mechanical properties. Due to the lower component mass, the stress is lower. This and the high strength of the fiber-reinforced composites allow a significant increase in rotational speed. The combination with metallic components, such as for the shaft connection or connecting elements for load introduction, leads to the implementation as innovative hybrid metal-fiber composite designs (MFB). In terms of power density ( space, flow rate and speed), robustness, service life and degree of integration, it offers considerable advantages over conventional solutions.

Significant improvements in manufacturing costs and maintenance

Modular MFBs also allow the realisation of multi-part impellers, resulting in significant improvements in manufacturing costs and maintenance. Due to the modular design, impellers can be realized in the future which allow highest circumferential speeds over a long operating period under critical thermomedial conditions for monolithic designs and allow an economical production even with small quantities. The ILK scientists will pursue the promising results of the feasibility study in a follow-up project.

Dr.-Ing. Sebastian Spitzer

Head of Lightweight design

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 2, Room 250 Holbeinstr. 3

01307 Dresden

Deutschland