Nov 23, 2021

Flexural and torsionally stiff components for geared engines

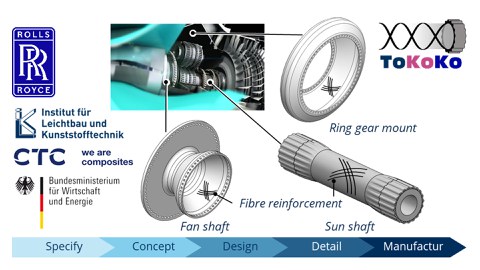

Section of the Rolls-Royce Power Gearbox (top) with the flexible and torsionally stiff fibre-reinforced plastic composite structures to be investigated in the ToKoKo project: fan shaft, sun shaft and ring gear mount.

In the project "Torsionslastübertragende Komposite Komponenten” (ToKoKo), the Institute for Lightweight Design and Polymer Technology (ILK) at TU Dresden is investigating the use of fibre-reinforced plastic composites (FRP) in safety-relevant structures in the power gearbox of future engines on behalf of Rolls-Royce Deutschland Ltd & Co KG together with CTC GmbH.

During aircraft manoeuvres, gyroscopic forces occur as a result of changes in the position of the rotating engine, which counteract this change in position. This creates constraining forces in the power gearbox, which can lead to increased stresses in the gears and thus reduce their service life. Fibre-reinforced plastic composites with their direction-dependent and adjustable properties allow the design of drive components such as the fan shaft, the sun shaft or the ring gear mount, which are simultaneously flexible with high torsional strength and can thus contribute to a significant reduction in the loads inside the engine.

The use of fibre-plastic composites for such drive components, in the context of interacting individual disciplines during development (design, dimensioning and manufacturing), is being investigated as part of the ToKoKo project.

The project is funded under the Sixth Aviation Research Programme (LuFo) of the Federal Ministry for Economic Affairs and Energy BMWi.

Contact:

Dr.-Ing. Sebastian Spitzer

Head of Lightweight design

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 2, Room 250 Holbeinstr. 3

01307 Dresden

Deutschland

Radka Roßner (Tomečková) M.A.

International affairs

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Lightweight Engineering and Polymer Technology

Visitors Address:

DÜR, Floor 2, Room 259 Holbeinstr. 3

01307 Dresden

Deutschland