Facilities

The Chair of Flight Mechanics and Controls is located in a listed builidng in Marschnerstraße Nr. 28 in Dresden's Johannstadt.

Facilities

The large wind tunnel is of the Göttingen Type with a closed curciut, but it has an open Test section. This allowes for best possible access to the test objects, particularily concerning flow visualization.

Learn More

The trainer, also known as the vacuum or high-altitude wind tunnel, is primarily used to model effects in gas-kinetic flows with very high Knudsen numbers, as they occur in the initial phase of reentry.

Learn more

This equipment is mainly used for the calibration of measuring instruments as well as simple experiments within the scope of student training.

Learn more

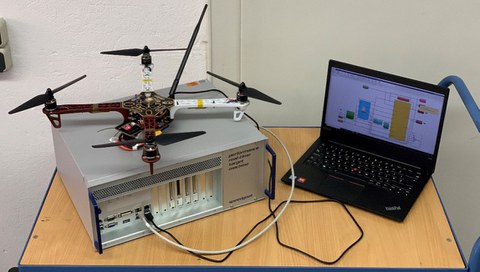

The Chair of Flight Mechanics and Control operates several unmanned aerial systems for research and teaching. Current research topics include wind tunnel-based system identification and the testing of energy-optimized flight paths for UAVs in urban areas/environments. Pixhawk is used as an autopilot and flight control system in combination with MATLAB Simulink and the open source software PX4. The Chair also has a Speedgoat Real Time Target Machine for rapid prototyping of flight controllers and hardware-in-the-loop tests prior to flight tests.

UAVs are developed and manufactured independently at our Chair. The airframes consist of a hybrid structure made of wood, CFRP and 3D-printed materials such as LW-PLA, PLA and PETG. This combination of materials enables the production of robust lightweight structures with minimal manufacturing effort. Thanks to modular construction concepts, the aircraft can also be flexibly adapted to different research purposes.

Flight systems

UrbanCondor

The UrbanCondor uses the fuselage of the Sig Kadet LT-40 with a reinforced nose landing gear. The special feature of the UAV is the wing, which is completely 3D-printed apart from the CFRP spar. Thanks to screwable clamp connections, the wing design does not require any glued joints, which considerably simplifies repairs and modifications (increasing the wingspan, installing multi-hole probes, etc.). The robust design and landing flaps also enable the transportation of large payloads.

SIG KADET LT-40

- Wingspan: 2m

- Take-off weight without payload: 5.1kg

- Maximum payload: 2kg

- Speed range: 45-130km/h

- Maximum flight time: 20min

SchubiOne

The SchubiOne serves as a model for the UAVs developed as part of the design project. In its design, the focus was on consistent lightweight construction and generously dimensioned tail volumes. The resulting low stall speed and high inherent stability make it a good entry-level aircraft for pilot training.

SchubiOne

- Wingspan: 1.5m

- Take-off weight: 2.8kg

- Speed range: 30-110km/h

- Maximum flight time: 25min

Quadrocopter (BX1)

The BX1 is used as part of the course to test the control engineering content learned during the course using a practical example. The primary focus here is on modeling and the development of position controllers and initial autopilot systems. The BX1 is also used to simulate the dynamics of other spacecraft, in particular landers. Under certain boundary conditions, control algorithms developed for spacecraft can be tested in the open field.

Quadrocopter

- Propeller diameter: 0.4m

- Take-off weight without payload: 1.2kg

- Maximum payload: 0.4kg

- Speed range: 0-50km/h

- Maximum flight time: 25min

History

Project planning for the wind tunnel started in 1954 under the direction of Professor W. Richter, head of the intstitute for applied aerodynamics of the faculty for aeronautics in these days. Preliminary investigation had been conducted by the professors Albring and Klose. The foundation stone was layed in 1955. Due to shortage of funding construction work were being interupted from january 1957 to april 1958. Afterwards, the research center of the aeronautical industry was responsible until 1961. An expertise initiated by Prof. Albring proved the importance of the wind tunnel for education and aerodynamic research in the GDR. This way, demolition of the wind tunnel tube and use of the building for other purposes could be prevented. However, employees had to acquire all fund on their own until 1968. Then, after reformation of the universities in the GDR, the wind tunnel was integrated into the division of fluid mechanics.