Aug 14, 2025

Successful Testing of TU Dresden’s EPP Drilling Tool at TNO Rig

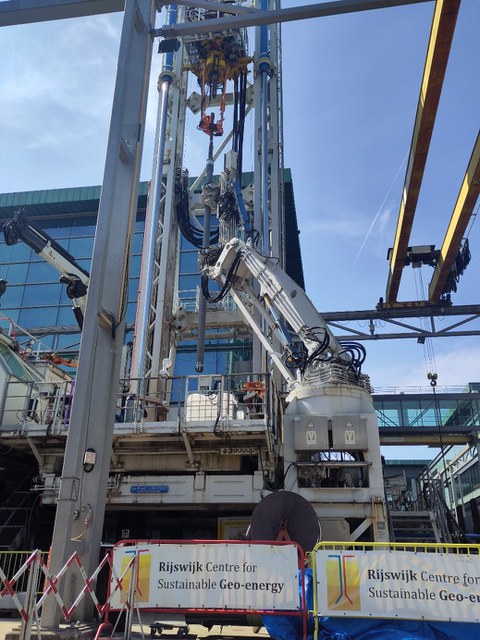

In June 2025, the newly developed Electro-Pulse-Power Drilling System (EPP) from TU Dresden was successfully tested in two key experiments on the state-of-the-art drilling rig operated by TNO in the Netherlands — a major milestone in advancing deep drilling technology.

1. Functional Test of the Pulse Generator

In the first test, the high-voltage pulse generator was assembled and connected to a charging unit capable of delivering up to 40 kV. Grounding was ensured via the wellhead of the research borehole. After setup, the generator was successfully switched on, and the spark-gaps in the respective stages of the pulse voltage generator ignited reliably and in the expected sequence. The generated pulses were stable and confirmed the functional readiness of the generator for integration into the drilling tool.

2. Rig Test of the Complete EPP Drilling Tool

In the second experiment, the pulse voltage generator was installed into the EPP drill bit prototype, which was then handled using the conventional pipe handler and elevator of TNO’s drilling rig. The prototype was safely positioned in an IBC container filled with water, mounted on the rotary table, and electrically connected to both the newly established high voltage supply and grounding system. The test demonstrated that the EPP drilling tool can be deployed and operated on a conventional rig without any issues. No electromagnetic interference was detected in surrounding electronic systems, proving the tool’s safe operation.

The interdisciplinary nature of the campaign makes the results highly relevant for the continued development of this innovative drilling technology. The valuable technical insights gained from these experiments are now being used to further improve the EPP drilling system. In the next phase of the project Deeplight, large-scale drilling experiments will be conducted on the TNO rig. These tests will focus on optimizing drilling parameters and experimentally validating the circulation and removal of rock cuttings under realistic downhole conditions.