GeLager

Wartungsfreies und verschleißarmes Lager

| Finanzierung: |

AiF - Arbeitsgemeinschaft industrieller Forschungsvereinigungen „Otto von Guericke“ e.V. IGF - Industrielle Gemeinschaftsforschung |

| Förderkennzeichen: | IGF-Nr.: 18 382 BR/1 |

| Laufzeit: | 10/2014-01/2018 |

| Kontakt: | Christian Stentzel |

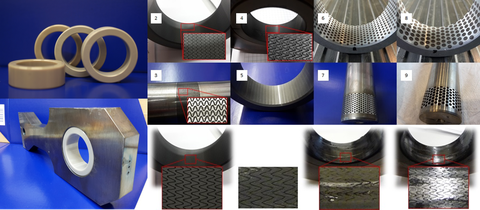

Gleitlagerungen aus Hochleistungskeramiken bieten ein hohes Potenzial zur Verschleißreduzierung und Schaffung einer Wartungsfreiheit von oszillierend betriebenen Gleitstellen im Bereich der mobilen Arbeitsmaschinen. Neben dem Verzicht auf zyklische Nachschmierungen oder Zentralschmierungen werden verschleißbedingte Buchsenwechsel vermieden. Ebenso wird ein Austrag von Schmiermitteln in die Umwelt gemindert.

Dabei liegt der Fokus des Projektes auf das keramikgerechte Design, welches die umgebende Struktur mit einbezieht. Insbesondere die Einbettung aber auch der Bolzen sind durch konstruktive Maßnahmen zu adaptieren, sodass eine möglichst geringe Zugspannung unter Last im keramischen Werkstoff entsteht. Parameterstudien mit Hilfe der FEM erlauben die Aufstellung von Anforderungen an das Design nach dem Kriterium des Spannungsminiums und in Abhängigkeit der Lagergröße und -belastung sowie des verwendeten keramischen Werkstoffes. Eine experimentelle Validierung des keramikgerechten Designs bestätigt eine statische und dynamische Tragfähigkeit bis mindestens 150 N/mm². Weiterhin wird ein Weg eines fluidfreien und wartungsfreien Tribologiesystems für keramische Werkstoffe aufgezeigt, das einen geringen Reibwert von kleiner 0,1 und einen nicht messbaren Verschleiß aufweist. Optimierungspotenzial besteht hinsichtlich des erreichbaren Gleitweges. Abschließend wird eine Berechnungsvorschrift zur Dimensionierung eines keramischen Gleitlagers gegeben.

Auf Hochleistungskeramik basierende Gleitlager sind somit ein weiterer Baustein zur Senkung der Betriebskosten und Steigerung der Ökobilanz einer mobilen Arbeitsmaschine.