Technical Equipment

For experimental purposes, the Institute for Fluid Power has a modern experimental field with a total size of 600 sqm. It consists of a hydraulic and a pneumatic area as well as two acoustic chambers.

The institute’s central hydraulic power unit

New hydraulic aggregat

For the supply of hydraulic test rigs with oil pressure, four independent hydraulic power units are available:

- Unit 1: 520 l/min, 350 bar, 180 kW,

- Unit 2: 300 l/min, 350 bar, 92 kW,

- Unit 3: 220 l/min, 350 bar, 90 kW,

- Unit 4: 95 l/min, 150 bar, 32 kW.

The central unit offers the opportunity to control pressure, volume flow, and hydraulic power. The unit's water cooling system with a cooling capacity of 200 kW makes it possible to implement test runs with different temperature profiles.

To run pneumatic test facilities, two compressed air supply systems with 10 bar or 30 bar respectively, each with a pressure vessel of 1000 l, are installed.

Measuring equipment

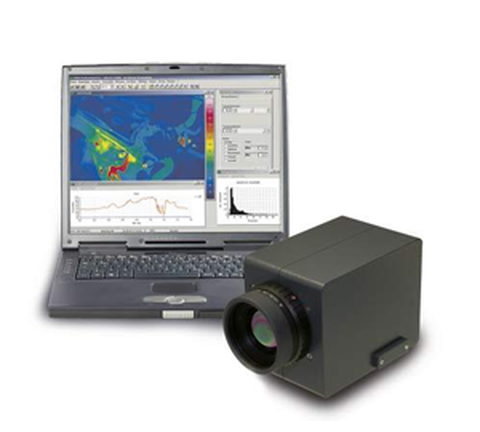

Thermal Imaging System (Photo: Firm InfraTec)

- PC-based data logging with

- digital measuring amplifier DMCplus© and MGCplus©

- dSpace© real time simulation and controller hardware

- dynamic performance measuring device 50 kW/ 80 kW

- high speed camera

- laser triangulation systems MicroEpsilon ILD2220-2

- Laservibrometer Polytec OFV-5000

- thermographic system InfraTec VarioCAM

- measuring microscope Leitz Ergolux

- sound and vibration measuring system:

12-channel Portable PULSE System (Brüel & Kjær)

Computation/Simulation Software

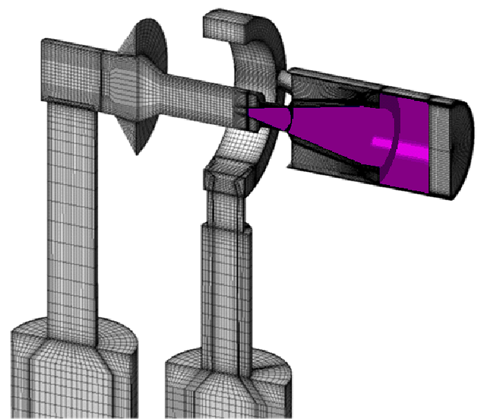

CFD-mesh of pressure relief valve

For processing simulation tasks, the institute has powerful workstations as well as access to TU Dresden’s high performance computers. The following software tools are usually used:

- ANSYS-Workbench

- ANSYS-Fluent, ANSYS-CFX for flow calculations

- ANSYS for various FEAs (magnetic calculations, harshness, temperature fields)

- Maxwell for magnetic field computation

- ITI SimulationX, Matlab/Simulink for dynamic system analysis

- OptiY for numeric optimizations