Dec 15, 2022

Efficiency increase, wear reduction and lead-free operation of axial piston pumps through meso-structured slippers

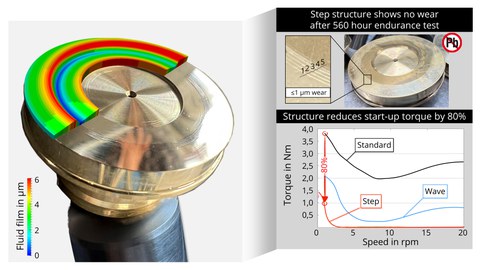

Lead-free structured slippers reduce start-up torque and wear in axial piston pumps

Due to the rise in the electrification of hydraulic systems, hydrostatic pumps experience a new challenge in terms of operating speed. Especially at low speeds, pumps must be able to hold loads without running into mixed friction and wear. Today, some pumps can still withstand these conditions, mainly because they use leaded metals in their sliding bearing. However, these are to be replaced by lead-free materials in the near future to comply with European regulations (Reach Regulation).

Meso-structures are surface designs that allow for small changes in height (in µm range) over longer distances (in mm). This structuring allows to selectively change the pressure field in the gap and builds up additional hydrodynamic pressure.

In the recently completed "Wave Pump" project, different structures on the slipper sealing land were tested and optimized using numerical simulation (Caspar FSTI). The two best structures, a ±6 µm wave and a 6 µm step design, were subsequently manufactured and tested using near-series production. The structured slippers were compared with an unstructured slipper that was also optimized and represents the best possible design without surface structures.

As a result, the step slipper performed best. It achieved an overall efficiency improvement of 6 % at full stroke and 16 % at 25 % swashplate angle, both at low operating pressures and speeds. At the same time, overall efficiency did not deteriorate at any operating point, even at corner power (350 bar, 2300 rpm). For electrification, the start-up torque is particularly important, and the step slipper was able to reduce this by 80% at 1 rpm without generating more leakage. After a 560 hour endurance test, less than 1 µm of the 6 µm step wore off, which means that this design has virtually no wear other than in the surface roughness. This made it possible to test a lead-free slipper that was at no point inferior to the leaded brass slipper. The lead free slipper also passed the 560 hour endurance test with less than 1 µm wear.

You can find more information about this in our publication "Tribo-optimized lubricating interfaces in hydrostatic pumps with surface shaped slippers".

| Grant number: | 20757 BR1 |

|

Short title: |

Mesostrukturen in Gleitschuhen von Pumpen |

| Duration: | 01.08.2019 - 31.07.2022 |

| Contact: |