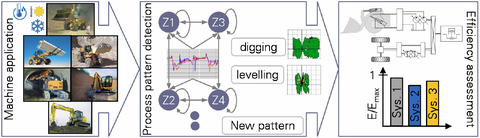

Efficiency assessment through operation point distribution

Research Task/Objectives

Nowadays, predefined standard cycles are used to develop and evaluate drive trains of mobile machines. But these represent just a small part of the real range of operational

conditions and load situations. For the evaluation of the whole range, measurements over large time periods are needed which result in a time-consuming analysis. Therefore, an automatic classification of the measurement data into operation point distributions on the machine and an allocation to single work cycles (pattern detection) shall be developed. To get representative statements about the systems energy efficiency without time-consuming simulations, calculations algorithms must be developed to connect the energy distribution at the systems output with the systems input.

Approach/Results

Based on an example application and an initially chosen work cycle, measurements built the starting point for development. The measured time series are both the basis

for the generation of a data structure for operation point distributions and their time superposition as well as the development of the process pattern detection. Within the

research project, a modeling approach that provides information on the efficiency of different drive trains based on the frequency distribution of the systems energy output will be developed. Furthermore, this description form will be validated with measurements or a system model and provided in a suitable calculation tool as a function library.

Range of application of mobile machines and the project goals deriving therefrom

This IGF Project 19613 BR/1 of the research association Forschungskuratorium Maschinenbau e.V. was supported via AiF within the programme for promoting the Industrial Collective Research (IGF) of the German Ministry of Economic Affairs and Energy (BMWi), based on a resolution of the German Parliament.

The final project report can be obtained from Forschungskuratorium Maschinenbau e.V. (mailing address: Lyoner Str. 18, 60528 Frankfurt am Main, E-Mail: info@fkm-net.de).