Adaptive model-based fault detection

Objectives

Hydraulic drive systems require modified system structures with extended control strategies in order to meet the increasing demands on mobile machines with regard to automation and efficiency. The constantly increasing complexity of the machines must not impair the safety of people. The aim of model-based fault detection is the permanent and real-time diagnosis of the machine behaviour to enable an immediate reaction to faults and component failures before these lead to dangerous situations.

Approach

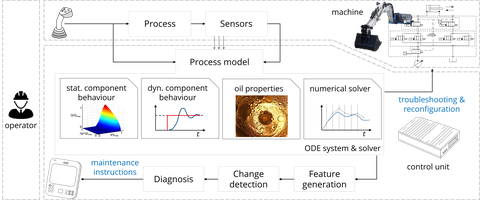

Based on real-time-capable models, which can be executed with the limited computing capacities of mobile control units, selected methods of model-based fault detection are evaluated with regard to their diagnostic robustness in simulations and on the test bench. Thereby, different modelling depths, limited sensory machine equipment and varying process conditions are taken into account. The analysis of deviations between the real system and the diagnostic model allows not only to detect errors, but also to draw conclusions about the cause of the deviations.

Results

A robust and easy-to-parameterize fault detection system was implemented in the project. Based on 12 parity equations, all dangerous fault conditions are detected quickly and reliably. Fault localization using expert knowledge enables the correct identification of faulty components with up to 91% localization accuracy. Based on this, fault-compensating measures were implemented to increase availability. The results could be fully verified on the test bench.

This IGF Project 20246 BR/1 of the research association Forschungskuratorium Maschinenbau e.V. was supported via AiF within the programme for promoting the Industrial Collective Research (IGF) of the Federal Ministry of Economic Affairs and Climate Action (BMWK), based on a resolution of the German Parliament.

The final project report can be obtained from Forschungskuratorium Maschinenbau e.V. (mailing address: Lyoner Str. 18, 60528 Frankfurt am Main, E-Mail: info@fkm-net.de).