Development of an automated pattern classification for the interpretable evaluation of machine data

Task / Objective

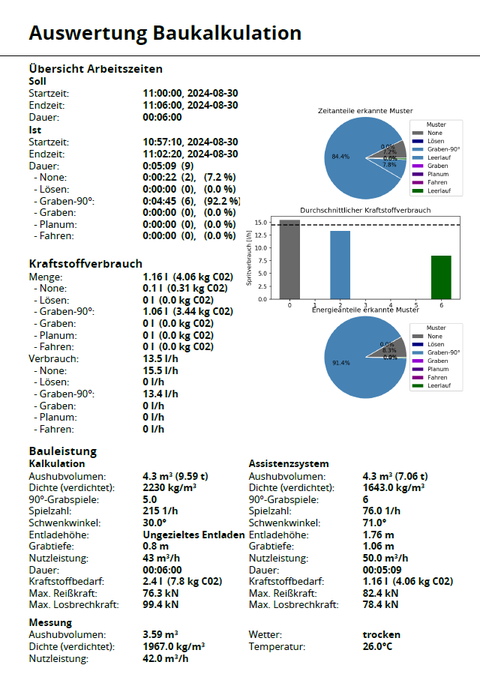

The objective of the project was to create a consistent evaluation option for the activities of mobile machinery. The overall system to be developed should include the recognition of a fully occurring usage collective of a mobile machine, as well as an evaluation of the work activity or operating behavior based on this. If conventionally available or calculable machine data is combined with the knowledge of work activities performed, work processes can be automatically evaluated and assessed. Such evaluations can be used, for example, with the aid of technological parameters such as mass handled per time or fuel consumption per mass handled, in order to evaluate and optimize deployment planning on construction sites or the operating behaviour of equipment operators.

Solution approach

The procedure for achieving the research objective was essentially carried out in four steps. To begin with, an 18-tonne wheeled excavator was selected as a demonstrator machine on which the detection and evaluation system was to be implemented in consultation with the project support committee (PA), and the focus within the research project was placed primarily on civil engineering activities. Furthermore, together with the PA, potentially suitable indicators / characteristics were defined in combination with target actors for the evaluation of work activities, with a general focus on topics such as energy and work efficiency, but also on construction costing, planning and monitoring.

Based on these definitions, various machine functions were developed by the two participating Chairs in a second step. FE 2 (Chair of Construction Machinery) focused on the development of a real-time-capable online method for activity recognition. The calculation of various real-time machine variables, such as the current loading mass or energy flows, was the focus of FE 1 (Chair of Fluid-Mechatronic Systems Engineering). It was important to agree on a uniform system architecture for the demonstrator, including defined interfaces for the machine functions. This allowed FE 1 to define evaluation functions for assessing the activities, which link the different information together and prepare it for various target actors, such as machine operators or contractors.

In the third step, the individual functions were implemented as software modules. With the help of software-in-the-loop (SiL) and hadware-in-the-loop (HiL) methods, the functionality of the individual software modules and the entire evaluation and detection system, including a GUI for operation, was tested in conjunction with real-time simulation models.

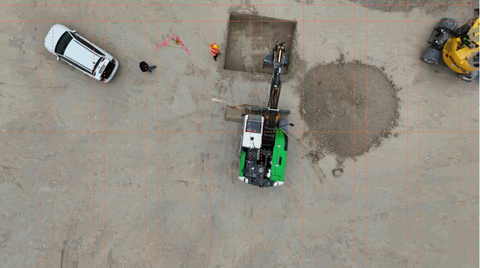

In the final fourth step, a detailed validation of the overall system was carried out in cooperation with Bau Bildung Sachsen e. V.. Various civil engineering activities were carried out under real operating conditions with machine operators of different qualification levels on a test site of the inter-company training center (ÜAZ) in Glauchau in order to check both the basic robustness of the developed solutions and the suitability of the defined features / indicators.

Results

The project provided extensive findings on the recording of typical earthmoving work performed by hydraulic excavators, as well as their evaluation and assessment. Pattern recognition is based on the evaluation of kinematic data such as tilt angles and cylinder pressures. The system recognized various process cycles, including idling, digging and leveling. Recognition rates of up to 98 % and a cycle time accuracy of 90 % were achieved. The functionality was validated under real-life conditions and proved to be robust even with inexperienced operators for unique patterns. These results form the basis for a higher-level evaluation system that enables a quantitative analysis and evaluation of individual operating styles. The project showed that linking conventional machine information, which is often already available today on control units or other hardware components of mobile machines, with information on work activities currently being carried out enables a reliable automated evaluation of work processes, thereby revealing enormous potential. The evaluation and recognition system can be used to generate helpful analyses, particularly for the target actors of construction contractors, machine operators and development engineers. For example, in a targeted manner, contractors can record the actual characteristic values of construction activities, such as useful output, excavation volume or fuel requirements, and compare these with the values assumed in the construction calculation. This makes it possible to check your own construction costing as well as the selection of machines and tools. Development engineers can create time- or activity-based reports on the energy efficiency of individual subsystems such as the diesel engine or valve block of the working hydraulics, including associated parameters such as average engine speeds or utilization. This allows a knowledge base to be built up that enables machine manufacturers to optimize the design of their machines in view of their actual use. In principle, machine operators can be provided with similar information as construction companies after completion of a construction activity, but also additional parameters such as the degree of simultaneity of joystick operation or the duration of active pressing of hydraulic cylinders in end stops, which should enable optimization of operating behaviour.

The research work presented was carried out within the project "Development of an automated pattern classification for the interpretable evaluation of machine data" (funded by the German Federation of Industrial Research Associations "Otto von Guericke" (AiF) organized in the Research Association for Construction Machinery and Building Material Plants e.V., IGF No. 01IF22483N). The authors would like to thank the Federal Ministry of Economics and Climate Protection (BMWK) for providing the funds.

Duration: 01.07.2022 to 31.03.2025

The final report can be obtained from the Forschungs-kuratorium Maschinenbau e. V. as the supervising research association (postal address: Lyoner Str. 18, 60528 Frankfurt am Main, e-mail: info@fkm-net.de).