Service-mobile - Development of a knowledge-based assistance system for service and maintenance of mobile machinery in construction industry

Task / Objective

Increasing efficiency, productivity and safety requirements are raising the complexity of mobile machinery in the construction industry. Nevertheless, these machines are subject to high availability requirements, as breakdowns usually cause high follow-up costs. Since maintenance and repair work on construction machinery usually requires service technicians with special knowledge, this is an enormous cost and time factor.

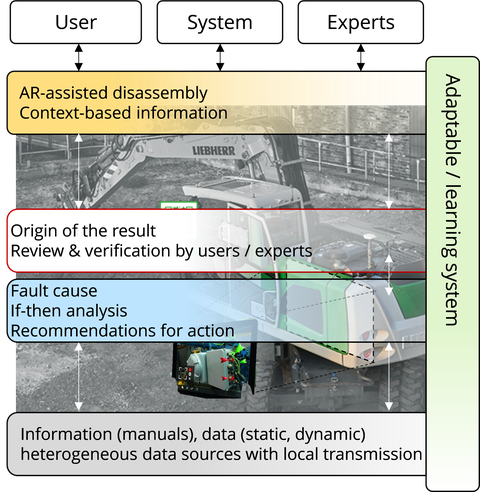

The goal of the project is the development of a digital, adaptive assistance system that contains expert knowledge in order to relieve the workload of back office staff and provide service technicians on site with quick access to important information. This can optimize the performance of maintenance and repair work. The integration of latest technologies such as AR (augmented reality) and XR (extended reality) should also enable people without specialist knowledge to carry out complex tasks.

Solution approach/Results

Based on a requirements and needs analysis for service issues, relevant use cases are defined which have the greatest potential for a software-supported assistance system. The identified need for research consists primarily of:

- the transformation of highly heterogeneous data sources into machine-readable form,

- the integration of AR/XR technologies for digitally assisted work

- and supported troubleshooting through integrated machine and component models.

The project investigates various approaches for providing analog machine information in the digital service tool and for managing the data in a shared knowledge repository. Based on this, algorithms for guided troubleshooting will be developed by integrating extended analysis functions and using models (digital twin). The generic design of the problem-solving system enables transferability to different application scenarios with little adaptation effort. The localization of faulty components and assemblies is enhanced by AR and XR content, which simplifies the localization and replacement of failed systems. Correct operating and assembly processes can be ensured by displaying content directly on/in the machine. The developed algorithms and solutions were implemented and verified in a demonstration scenario.

Results

The presented research activities are part of the project „netSENSORS -Service-mobile/ Entwicklung einer modellbasierten, lernenden Wissenskomponente auf Basis heterogener Datenquellen des wissensbasierten Assistenzsystems“ (Ref. No. 16KN111523), which was funded by the German Federal Ministry for Economic Affairs and Climate Action within the ZIM programme.

The results were developed in collaboration with FAB Bertelmann Technologie.

Duration: 01.09.2022 - 28.02.2025