Organical Dental Implant (R+K CAD CAM)

| Runtime | 07/2012 – 02/2018 |

| Funding | Through industry partners |

| Project staff | |

| Dr.-Ing. Stefan Holtzhausen | |

| Partner | R+K CAD/CAM Technologie GmbH & Co. KG (Berlin) |

Motivation

Establishment of fully computer-aided planning and production

Objective

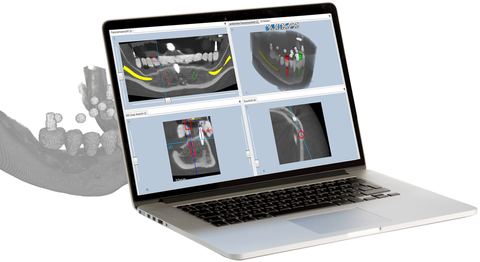

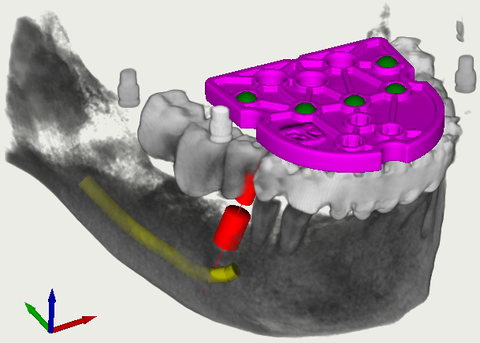

Development of a continuous reverse engineering/CAD/CAM process chain for the NC-supported production of drilling templates for dental navigation-assisted implantation

Project content

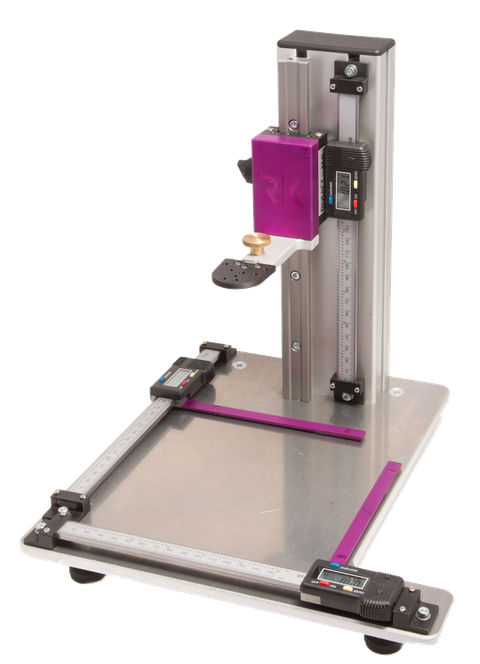

For the production of drilling templates, a completely computer-aided planning and production was established. The aim was to avoid unnecessary data transfers and expensive third-party products, while at the same time ensuring greater process reliability. A planning software was developed that is easy to use due to a logical functional sequence. For processing, the software offers the possibility of importing common CT and DVT data sets. Furthermore, innovative planning tools are available. For example, the software ensures the alignment and reduction of the data set, the creation of an arbitrarily curved panoramic view as well as an automatic registration of the data set to the production coordinate system via a developed registration plate with a defined number and arrangement of registration spheres. Furthermore, an implant database is connected for planning and the export of a planning protocol (PDF) is possible. The export of the implant and drill sleeve positions takes place in a neutral exchange format (currently: IGES, XML). The manufactured template is checked with the help of a designed and implemented test table.

Additional information

R+K CAD/CAM Technologie GmbH & Co. KG:

In addition, you can find a summary poster of the project here