ESF-Plus Junior Resarch Group CARBONCYCLE

Table of contents

CARBONCYCLE (Innovative bio-chemical processes for the industrial utilization of CO2)

The European Union offers a variety of funding programs to support research and education as a valuable public good. Our project was funded by the European Regional Development Fund (ESF-Plus).

Brief description

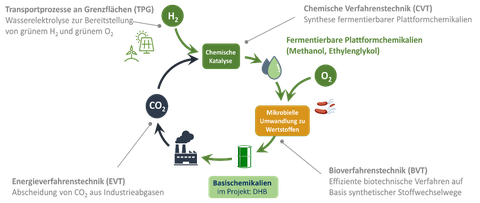

Efficient, industrially relevant strategies for the use ofCO2 must be developed in order to halt the rapid pace of climate change. Although it is already possible in principle to reduceCO2 to basic chemicals with the aid of hydrogen using current technology, the industrial implementation of these processes is failing due to the insufficient increase in the value of the products compared to the costs of the processes. In this project, this problem is to be solved by a coupled bio-chemical synthesis of higher-priced products and the removal of technical obstacles in a targeted manner.

In order to be able to map the entire process chain fromCO2 to the product in the project, an interdisciplinary junior research group was founded, whose members have all the necessary skills for processing and coordinating the individual process steps. In their work, the junior researchers can draw on the existing expertise of the Chair of Energy Process Engineering (EVT), Chair of Transport Processes at Interfaces (TPG), Chair of Chemical Process Engineering (CVT) and Chair of Bioprocess Engineering (BVT) at the TUD Dresden University of Technology and are closely supervised by the specialists working there.

The capabilities of the process approach will be demonstrated using the example of the synthesis of 2,4-dihydroxybutyrate (DHB). DHB is an extremely versatile basic chemical. Its main field of application is the synthesis of the methionine analog HMTB, which has so far been obtained exclusively from fossil raw materials and has an annual production volume of 1.2 million tons. Furthermore, DHB is currently being intensively researched as a new monomer for the production of innovative biopolymers. Due to the additional OH groups of DHB-containing co-polymers, these are more hydrophilic and can therefore be expected to have improved biodegradability and (through controlled cross-linking of the OH groups) interesting mechanical properties. The development of bio-chemical production processes for DHB will therefore make a significant contribution to reducing the use of fossil raw materials and to the production of highly innovative biopolymers.

Project duration

01.01.2024 - 31.12.2026

Project partners:inside

TUD-internal project partners

Chair of Bioprocess Engineering (project management)

Chair of Transport Processes at Interfaces

Chair of Chemical Process Engineering

Chair of Energy Process Engineering

Contact

© Ritz

© Ritz

Prof. Dr.-Ing. Thomas Walther

Send encrypted email via the SecureMail portal (for TUD external users only).