POET - Development of an efficient biotechnological production process for the sustainable chromophore xylindein with multifunctional use in finishing technology

Mushrooms and mushroom-based products have great potential for the development of a resource-conserving and sustainable economy. In addition to enzymes, aromas and pharmaceuticals, natural dyes can also be obtained biotechnologically from mushroom mycelium. Mushroom fruiting bodies have been used for dyeing for centuries, with intensive dyeing results, as numerous mushrooms have the ability to produce dyes. For example, intensely green-colored wood can be found through natural colonization with the green cup fungus(Chlorociboria aeruginascens). This fungus produces xylindein, a complex, blue-green dye of the naphthoquinone group with bioactive effects. The wood used to be collected for handicrafts, in particular inlay work (Fig. 1), and shows very good color stability. However, extracting the dye from the wood or the tiny fruiting bodies is not economically viable.

Abbildung 1: Blaugrüne Färbung von Holz (Foto: A. Werner)

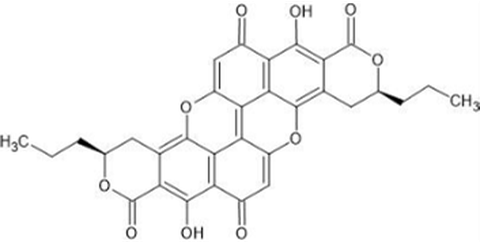

Abbildung 2 Struktur von Xylindein

There is no known chemical synthesis route for the dye and therefore no industrial process for its production. A first alternative is the fermentation of the fungus C. aeruginascens, where the mycelium of the fungus is cultivated in a bioreactor, thus utilizing the potential for dye production, which is genetically encoded in the cells of the fungus. The fungus is available as a pure isolate and initial microbiological tests also show the growth characteristics. Intense mycelial staining by xylindein has already been achieved with fermentations in complex media (Fig. 3).

The project has two objectives:

- Development of a continuous, efficient, large-scale and robust fermentation strategy with good xylindein formation in the fungal mycelium

- Development of an extraction process suitable for industrial use to obtain the dye from the mycelium for dyeing textiles and wood

Vat dyeing processes for natural (cotton) and synthetic fibers (polyethersulfone - PES) are to be used for dyeing (partner ITM). In addition to the dye extracts, the dyed fungal mycelium will also be used for dyeing textiles and wood-based materials (HFT).

Abbildung 3 Bioreaktor mit Chlorociboria aeruginascens Kultur (Foto M.Zschätzsch)

Based on the findings to date, experimental plan-based liquid fermentations are being carried out to improve dye production. The cultivation conditions (temperature, pH value, oxygen saturation) and the nutrient compositions (carbon, nitrogen, trace substances and percusors) are examined in parameter studies. In addition to the nitrogen deficiency, which has already been identified, the question is whether there are already uncolored precursors of the dye in the mycelium and how these can be converted into xylindein. All the results obtained will be used to scale up to a scale of 55 liters.

Project funding:

IGF

- Federal Ministry of Economics and Climate Protection (BMWK)

Project management:

© TUD

© TUD

Project researcher

NameDr.-Ing. Anett Werner

Head of enzyme technology

Send encrypted email via the SecureMail portal (for TUD external users only).

Cooperation partner:

- Institute of Textile Machinery and High Performance Material Technology (ITM), TU Dresden

ITM Institut für Textilmaschinen und Textile Hochleistungswerkstofftechnik

- Institute of Natural Materials Technology - Chair of Wood Technology (HFT)

HFT Professur für Holztechnik und Faserwerkstofftechnik

Project duration:

01.11.2024 - 30.04.2027