Experimentally supported basis models for a feasible numerical cleaning simulation 2

Regular and reproducible cleaning is carried out with automated cleaning equipment that is permanently installed in the machine (Cleaning-in-Place, CIP). Oversizing of the cleaning process is often accepted due to a lack of suitable design tools for optimization. This leads to a reduction in productivity and an environmentally harmful waste of water, chemicals and energy.

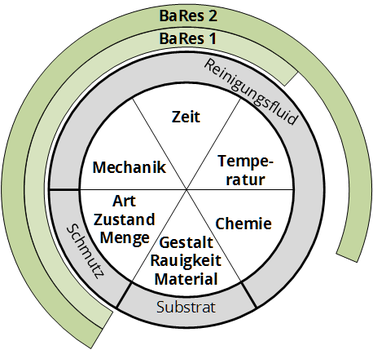

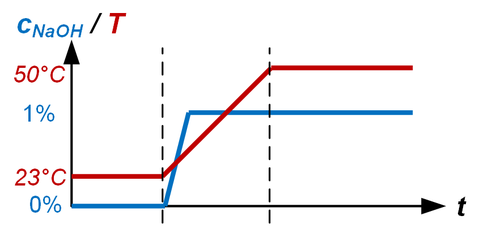

The aim of the project is to further develop suitable numerical models for the different cleaning mechanisms, which are characterized by a good prediction quality in the determination of the cleaning time as well as practicable computing durations for SMEs. The proposed approach combines a flow simulation (CFD) of the cleaning fluid for an arbitrary shape of the cleaning good with a boundary condition that models the soil behavior. This is a prerequisite for carrying out an optimization for a wide range of industrial cleaning processes in the future through numerical simulations. These are usually carried out in several cleaning steps with liquids of different chemical composition and temperature. Not only a change in the removal rate is possible due to a change in the cleaning fluid, also a change in the cleaning mechanism may occur during a multi-step cleaning process. The extended models will be developed using the knowledge and data obtained in previous projects, supplemented by further experimental and numerical investigations, and will be able to represent these effects and interactions.

Simulation-based cleaning prediction enables the industries concerned for a wide range of problems in the field of cleaning to reduce both the effort required for process development and the resources required for operating the cleaning process.

Project financing:

This research project is supported by the Industrievereinigung für Lebensmitteltechnologie und Verpackung e. V. (IVLV), the Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e. V. (AiF) and the Federal Ministry of Economic Affairs and Energy (IGF 21334 BR).

Project duration:

01.01.2021 - 30.04.2024

Project leader and contact:

© Köhler

© Köhler

Cleaning Technologies

NameDr.-Ing. Hannes Köhler

Research Field Coordinator

Send encrypted email via the SecureMail portal (for TUD external users only).

Cooperation partner: Technische Universität Dresden, Institute of Fluid Mechanics, Chair of Fluid Mechanics