Development of a water jet tester for verifications according to DIN EN ISO 16925 as a portable measuring device

Water jet tester

The quality of coatings (e.g. paint coating of car body parts in the automotive industry) is crucial to comply with quality standards, to avoid recourse claims and not to damage the reputation of a company. Therefore, it is necessary to check the coating quality regularly.

DIN EN ISO 16925: 2014-06 describes a standard test method for testing the resistance of paint coatings to pressurised water jets. A water jet tester shall be used for carrying out this test method.

According to this standard, the specific spray pattern of the flat fan nozzle has to be observed for comparable tests. In the current applications, this is checked visually with the help of hard foam blocks. The evaluation of theses blocks is time-consuming and operator-dependent; hence, the test results of the coatings can deviate.

An automatic measurement of the spray pattern and evaluation of the results would significantly simplify the evaluation of the current setting and the nozzle used.

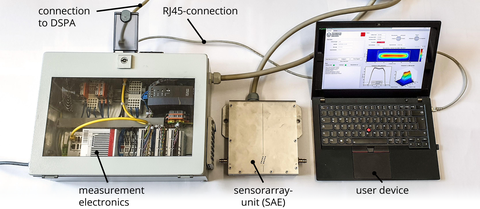

In the ZIM project Düsenstrahlprüfanlage (ZF4100933KO8) an automated, portable measuring system for high-pressure nozzles is developed in cooperation with Walter Gerätebau GmbH. The measuring system is preferably designed as a sensor array with several measuring points in order to reduce the measuring time. This includes the software-supported evaluation of the measurement data and the derivation of recommendations for the user. In addition, a calibration device adapted to the measuring arrangement is developed to guarantee consistent measurement results.

Results

The aim of the project was to develop a jet testing system (DSPA) for testing high-pressure nozzles. The novel DSPA in combination with the developed high pressure measurement system reduces the measurement time from 120 min to less than 10 min. This is possible by read several force sensors at once with 10 kHz, which were arranged as a sensor array. A subsequent algorithm analyzes the measurement data and provides the local impact force as a quantitative measure for objective evaluation of the nozzle quality.

This research project is supported by the Federal Ministry for Economic Affairs and Energy (BMWi) by decision of the German Bundestag.

Project duration: 10.2018 – 11.2020

Project management and contact:

Project leader: Prof. Majschak

Project manager: Dipl.-Ing. Manuel Helbig

© Nils Eisfeld

© Nils Eisfeld

Cleaning Technologies

NameDipl.-Ing. Manuel Helbig

Wissenschaftlicher Mitarbeiter

Send encrypted email via the SecureMail portal (for TUD external users only).