Ultrasonic Enhanced Embossing - uSEE

Analysis of the effect of ultra-high frequency vibrations on the deformation of fiber-based materials by embossing in discontinuous and continuous processes.

-- Automatic Translation--

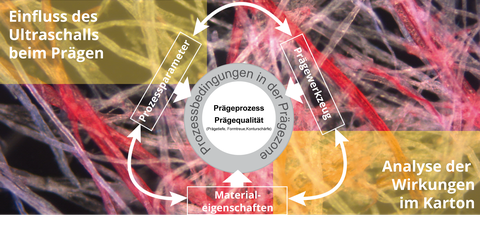

In addition to the development of an objective and reproducible evaluation methodology for embossing results and a test and analysis methodology for characterizing the embossing process, the primary objective of the research project is to assess the effect of ultrasound on the process- and material-dependent quality and forming parameters in the forming process of embossing fibre materials.

In the research project, the dependencies and correlations between physical, mechanical and chemical material properties and the ultrasonic parameters are determined with regard to the influence on the discontinuous and continuous embossing process and the resulting achievable embossing quality in the fiber material.

Furthermore, the interactions between the substrates to be embossed and the ultrasonically superimposed embossing tools are investigated. The findings on the influence of the substrate (e.g. pulp density, fibre length, fibre type) and the main influencing variables of the embossing process, such as: the embossing parameters (ultrasonic duration, frequency, amplitude), the tool geometry (slip, embossing height, flank angle), serve to enable the manufacturers of embossing machines to develop efficient and functionally optimized embossing tools. In combination with the developed evaluation, testing and analysis methodology, the developers and users of embossing technologies are enabled to assess the suitability of the material to be used and to determine the achievable embossing quality in advance by means of simple and standardized replacement tests.

The ultrasonic superimposed embossing of fiber materials represents a decisive step in the further development of embossing technology, with which the process limits and the achievable embossing quality can be increased by leaps and bounds. The targeted research results will open up new opportunities for medium-sized companies operating on the global market in the food and packaging machinery sector, which includes packaging manufacturers, packers and packaging machine manufacturers, for example, in the visual and haptic design of packaging solutions, further development potential for system technology in the area of consumer goods production and embossing tool design, as well as the possibility of material optimization compared to existing products for the conventional and ultrasonic superimposed embossing process in the area of raw material production. The research results will be used to demonstrate the process engineering potential that will allow the participating companies to develop innovative products and ultimately gain access to new markets.

Project funding:

The IGF project 19717 BR of the Forschungsvereinigung Industrievereinigung für Lebensmitteltechnologie und Verpackung e.V. was funded by the Federal Ministry for Economic Affairs and Energy via the AiF as part of the program for the promotion of joint industrial research (IGF) on the basis of a resolution of the German Bundestag.

Project duration:

10.2017-07.2020

Project management and contact:

Project management:

Prof. Dr.-Ing. Jens-Peter Majschak

Project management: Dipl.-Ing. André Hofmann

Cooperation partners:

HTWK Leipzig; Institute for Printing, Processing and Packaging