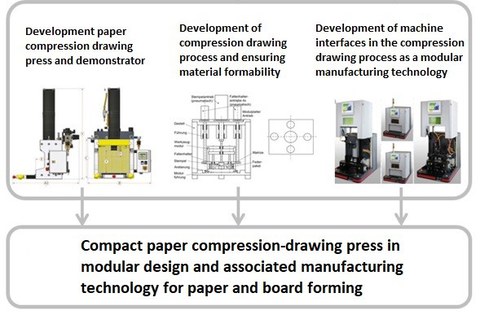

Development of a compact paper compression-drawing press in modular design and the associated manufacturing technology for paper and board forming

Conventional plastics have established themselves in the packaging industry primarily because of their protective properties, forming behaviour and variety of shapes. Fibre-based materials such as paper and cardboard offer an alternative in terms of renewable raw materials and recyclability and can contribute to an effective reduction in the amount of plastic in packaging. The compression drawing process has proven to be advantageous for the production of moulded parts. The aim of the project is to develop a production technology for paper and cardboard forming by compression drawing and a corresponding drawing press in modular design. The focus is on a compact and simple design of the press, as well as a fast and flexible changeover of the tools for different packaging materials and package formats.

Project funding:

This ZIM research project is supported by the Federal Ministry for Economic Affairs and Energy (BMWi) by decision of the German Bundestag.

Project duration:

03.2020-02.2022

Project management and contact:

Project leader: Prof. Jens-Peter Majschak

Project manager: Dipl.-Ing. Peter Gellerich

Cooperation partner:

Gechter GmbH

Steinbeis Hochschule, Lehrstuhl für Verpackungsmaschinen und Verpackungstechnik