Dec 01, 2021

BioRePly

BioRePly table

Development of bio-based recyclable layered composites

| Duration | 12/21 - 08/24 |

| Funding: BMEL | BMEL | FNR |

| Funding code | 2220HV093 |

| Contact | |

| Keywords | laminated veneer lamination, plywood, biodegradable, extended recycling |

BioRePly stands for biological materials that are processed into recyclable laminated wood materials (plywood). The project was concerned with the further development of the BioRePly material and the investigation of its reuse possibilities. To this end, the project was divided into two areas.

- Development of bio-based plywood and evaluation of the biological durability and weather resistance of this composite

- Evaluation of possible end-of-life scenarios and life cycle assessment of the life cycle of bio-based plywood(Institute of Waste Management and Circular Economy)

Results

BioRePly samples are more resistant to white rot than conventional veneer composites.

In comparison, 11-ply birch veneer-polylactic acid composites have the highest strength and stiffness. They could be classified (DIN 636) as F60/F70 and E80/E100.

The type of wood (birch, beech) has no influence on the resistance to white rot.

The fungal infestation on laminates with a lower layer thickness (11 layers) is higher than on laminates with thicker individual layers (5 layers).

The top layer material thermo veneer has a high average strength value after weathering and visually shows the least weathering, and is therefore favored as a top layer.

In order to obtain certification for biodegradability, PLA must degrade to 90%CO2 and water at 58 °C within 3 months.

The results of our own tests show that the PLA veneer woods always separated from each other and signs of PLA degradation were observed when sufficient water was available for hydrolysis at T > 58 °C.

Industrial composting (up to 70 °C) would therefore be possible, but degradation in biogas plants (T = 40-50 °C) and in nature or home composting (< 40 °C) would not.

An added value of the PLA-wood composite can be the composting of wood, which can contribute to the preservation of soil quality due to its high humus formation rate. This could become more important in the future due to a possible EU soil control regulation.

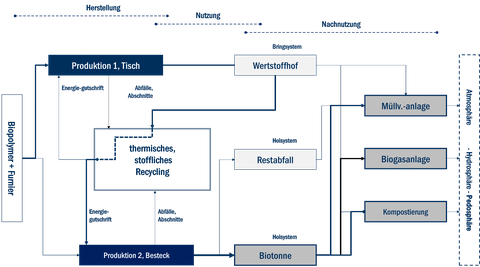

BioRePly Stoffströme in der Herstellungs-, Nutzungs- und der Nachnutzungsphase

Funding reference

© BMLEH

© BMLEH