Sep 01, 2023

CellFormDesign

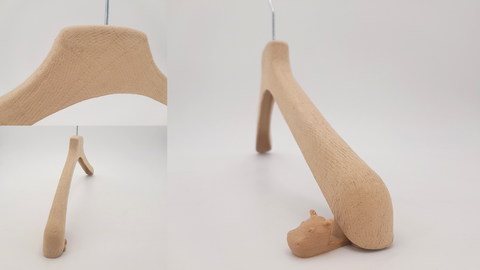

CellFormDesign bracket and impressions of the processing

Development of design concepts (form follows function) and investigation of weathering resistance for molded cellulose parts using the product example of clothes hangers

| Duration | 09/2023 - 08/2025 |

| Funded by | BMEL | FNR |

| Funding code | 2222NR019B |

|

Contact: Alfred Dietl |

|

| Keywords | molded parts, natural fiber, hot pressing |

The aim of the project is the development of material-specific technologies for the production of recyclable clothes hangers based on natural fibers in economic utilization of plant residues and waste from agriculture as well as the secondary use of waste paper and cellulose without the addition of fossil polymers. CellForm refers to the cellulose-based material group that is being investigated and molded into hangers. The project will develop and evaluate material designs (formulations, structures, modeling, properties) and corresponding efficient processing and production processes, as well as create demonstration objects that will be used for tests in relevant application environments (validation). Using experimental material samples and multi-variant product prototypes, the applicability, usability and marketability of the solutions are subjected to an experienced test and evaluation scenario and customer-centric improvement potential is optimized in an iterative development process. Early market communication and evaluation of project progress with potential customers (co-creative customer feedback, application tests, concept studies at the Euroshop trade fair in February 2023) will ensure that targeted research and development is carried out during the project. The natural fibers (e.g. plant residues such as hops, waste paper, cellulose) are prepared (grinding) and further processed (wet pulp/fiber cake) and then rubberized/pressed and dried into components. No cost-intensive hot pressing systems need to be used. The vacuum press drying process patented by TU Dresden is used in the project as a compression and drying process. By comparing the material and energy expenditure in the production, use and after-use phases, the environmental impact of newly developed products can be compared with that of conventional products. The project is being carried out in cooperation with the German clothes hanger manufacturer Mawa GmbH.

CellFormDesign - Demonstrator

Funding reference

© BMLEH

© BMLEH