01.11.2012

MERGE - DFG Exzellenzcluster

Werkstoffe/Muster um das Chemnitz ConceptCar im DFG-Exzellenzcluster MERGE

Cluster of Excellence – Technologies for Multifunctional Lightweight Structures

|

Laufzeit |

11/12 - 10/19 |

|

Finanzierung |

BMBF | DFG |

|

Förderkennzeichen |

Exzellenzcluster, EXC 1075 |

|

Kontakt |

|

|

Schlagworte |

Leichtbau, Naturstoffe, Furnier, Biopolymer |

Ziel der Forschung im bundesweit ersten Bundesexzellenzcluster auf dem Gebiet der Leichtbauforschung war die Technologiefusion für multifunktionale Leichtbaustrukturen. Also die Fusion großserientauglicher Basistechnologien aus den Bereichen Kunststoff, Metall, Textil und Smart Systems zur Entwicklung ressourceneffizienter Produkte und Produktionsprozesse.

Über 100 Wissenschaftlerinnen und Wissenschaftler sowie Technikerinnen und Techniker aus insgesamt sechs interagierenden Forschungsbereichen forschten an der Technologiefusion zur Produktion multifunktionaler Leichtbaustrukturen für die Großserie.

Das Forschungsfeld „Textil-/Kunststoffbasierte Technologien“ widmete sich der Entwicklung von Verfahren zur Serienfertigung endlosfaserverstärkter Leichtbaustrukturen. Dazu wurden auf thermoplastischen Polymeren basierende Kunststoffverarbeitungsverfahren wie Spritzgieß- und Presstechnologien weiterentwickelt und optimiert, bspw. mit integrierten Textilverstärkungen. Neben der parallelen Verarbeitung mehrerer Kunststoffe gelang es, auch metallische und elektronische Komponenten direkt in die Bauteile einzubringen, sodass Hybridbauteile effizient und ohne aufwändige Fügeverfahren hergestellt wurden. Um eine umweltfreundliche und ressourcenschonende Produktion im Sinne der Nachhaltigkeit zu fördern, erfolgte der Einsatz von Naturfasern sowie biobasierten und bioabbaubaren Kunststoffen.

Teilvorhaben der Professur für Holztechnik und Faserwerkstofftechnik

Ziel der naturstofftechnischen Forschungsansätze der TU Dresden war es nachhaltige Produkte für den Leichtbau zu entwickeln. Diese neuen biobasierten Verbundwerkstoffe bestehen aus naturfaserverstärkten biobasierten Thermoplasten. Dabei wurde von der TUD der bionische Ansatz, den unzerstörten Naturfaserverbund des Holzes – hier dünne Holzfurniere – als Faserverstärkung zu nutzen, untersucht. Holzarten und Furnierdicken wurden variiert. Holzschonende Prozessparamter zur Verarbeitung von Furnieren und thermoplastischen Folien wurden untersucht. Gemeinsam mit den Projektpartnern wurden biobasierte Haftvermittler erarbeitet.

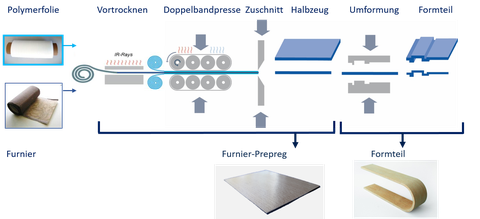

Prozesskette Halbzeug

Zudem wurden die erarbeiteten Furnier-Thermoplasthalbzeuge in verschiedenen Formgebungsverfahren zu beispielhaften Produkten verarbeitet. So konnte eine Gesamtprozesseignung gewährleistet werden. Final entstanden im Bauteile am Gesamtdemonstrator VW UP für In- und Exterieur, wobei eine Sensorintegration mit abgebildet werden konnte.

Bildcollage Produkte

- Evaluation of the bonding behaviour of thin bio-based wooden laminates

- Aqueous Poly (N-Vinylformamide-Co-Vinylamine) as a suitable adhesion promoter for wood veneer/biopolyethylene composite materials

- Natural unidirectional sheet processes for fibre reinforced bioplastics

- Maleic anhydride copolymers as adhesion-promoting reagent in wood veneer/biopolyethlyene composite materials

- Textil-/Kunststoffverarbeitungsverfahren mit nachwachsenden Rohstoffen S. 371 - 393

- Textil-/Kunststoffverarbeitungsverfahren mit nachwachsenden Rohstoffen; S. 419 - 439