Aug 01, 2023

FOMOP

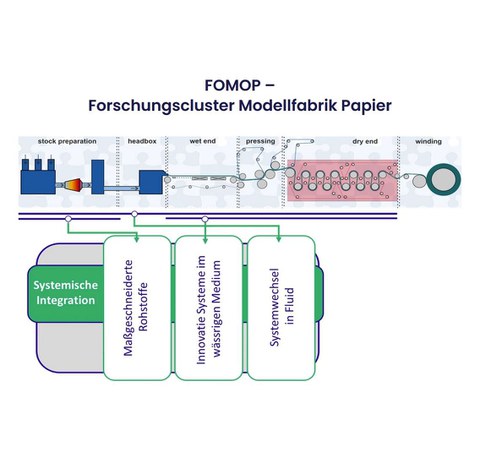

Core research areas in the FOMOP joint project

FOMOP - Forschungscluster Modellfabrik Papier

| Duration | 08/2023 - 07/2027 |

| Funded by | BMFTR | PtJ |

| Funding code | 03STG011D |

| Contact person | |

| Keywords | energy saving, resource efficiency, CO2 reduction, dry papermaking, dry fibers, dewatering |

Aim

Paper production is one of the most energy-intensive processes in the industry - thermal drying accounts for around 70 % of energy consumption. For over 2000 years, the manufacturing principles have followed the same pattern: fibers are suspended in water, prepared and then dewatered - first mechanically, then thermally.

As part of the FOMOP project (Forschungscluster Modellfabrik Papier), TU Dresden is pursuing the goal of fundamentally rethinking paper production:

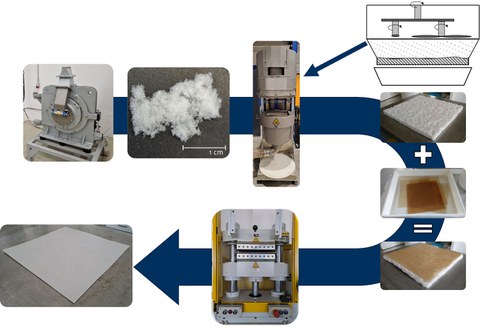

- Low-water or dry manufacturing processes are to be developed in order to reduce energy requirements by up to 80%.

- The focus is on new processes for stock preparation (defibration, fiber forming, fiber separation, stock blending) that are adapted to the requirements of low-water production.

- In addition, non-thermal dewatering technologies are being developed and analyzed that remove water with as little energy input as possible - for example through optimized pressing processes that lead to a higher dry content.

- The basic knowledge developed flows into the development of new types of technology platforms for energy-efficient, sustainable paper production.

With this contribution, TU Dresden is making a decisive contribution to the overarching goal of the research network: climate-neutral paper production by 2045.

Partners

- Modellfabrik Papier

- TU Darmstadt (MAP & PMV)

- RWTH Aachen (ITA)

- FH Aachen

- PTS – Institut für Fasern & Papier gGmbH

- Forschungszentrum Jülich

Links to

Funding reference