Feb 01, 2025

FusionPapStruc

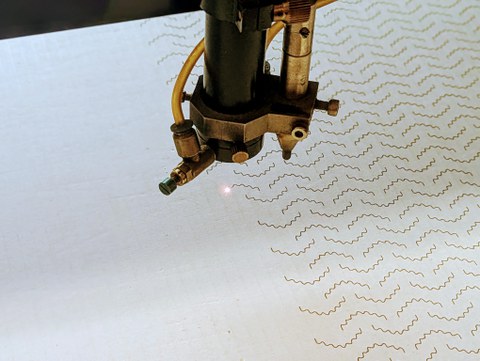

Laser pattern generation to produce a recyclable, energy-absorbing and moldable paper structure

Moldable energy absorbers made of paper

|

Duration |

02/2025 - 01/2027 |

|

Funding by |

ZIM |

|

Funding code |

KK5017840CM4 |

|

Contact |

|

|

Keywords |

corrugated board, packaging, energy absorber, moldable, laser, cutting pattern |

Aim

The aim of the project is to develop a moldable, energy-absorbing packaging material made of paper that surpasses previous solutions in its energy absorption capacity and can be completely returned to the waste paper cycle - as an alternative to plastic packaging.

To achieve this goal, Packwell Schweppnitz, a manufacturer of customized corrugated cardboard packaging, Lang Laser-System GmbH, a specialist in laser technologies, and TUD have joined forces.

The concept is simple, but the devil is in the detail. Special cutting patterns are designed to increase the formability of single wall corrugated cardboard so that it adapts to any contour. In order to ensure an economical process, standard feed speeds in the corrugated board industry are to be achieved, which can be up to 300 m/min. The innovative laser technology from Lang Laser-System GmbH is being further developed for this purpose. Not only the technology, but also the intelligent design of the cutting pattern plays a central role: it influences laser guidance, formability, strength and, in particular, the energy absorption capacity of the packaging material. The TUD is working intensively on pattern development and the influence of the respective geometries on the properties of the packaging material and comparing them with existing solutions. Packwell Schweppnitz is developing suitable, single-sided corrugated board structures to further optimize the absorption capacity.

Partner

- Lang Laser-System GmbH

- Packwell Schweppnitz

- Geometric Modelling and Visualization working group at the Institute of Geometry at TUD

Funding reference

© BMWK

© BMWK