Nested Honeycomb Core - new type of paper honeycomb core and process for production without adhesive

Together with the industry, a process for the production of an adhesive-free paper honeycomb core was developed at TU Dresden.

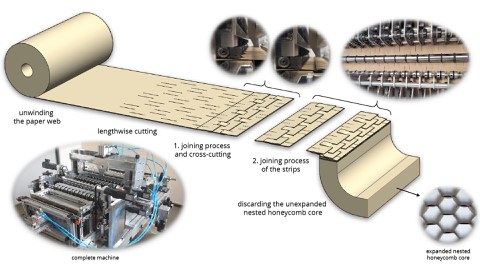

Production Process of Nested Honeycomb Core

Conventional expandable paper honeycomb cores are produced with adhesive. By applying a new principle for the production of an expandable honeycomb core (interlocking of individual paper strips, patented by TU Dresden), the use of adhesive can be completely dispensed with in core production.

The manufacturing process for the innovative “nested honeycomb core” involves the following steps: unrolling a paper web, creasing (optional), inserting longitudinal cuts, interlocking (nesting I) and cross-cutting the individual strips, pushing the strips together (nesting II) and depositing the nested honeycomb core for subsequent expansion. The development of a technology for inserting the strips into each other and pushing them together required particular effort. The figure shows a schematic diagram of the production of a honeycomb core according to the above production steps.

Due to the adhesive-free production process, the core tends to slip apart after the individual strips have been inserted into each other. Shear stress perpendicular to the expansion direction of the core should therefore be avoided. Since the expansion of the honeycomb core with a conventional expansion device for further processing is only possible to a limited extent, a machine technology adapted to this was developed, particularly with regard to the transport of the honeycomb cores through the expansion device.

The devices for producing the honeycomb core and for its expansion were developed together with partners from industry and implemented in test carriers. A patent application has also been filed for the manufacturing process.