Energy Materials

Table of contents

a) Metal-Organic Frameworks (MOFs)

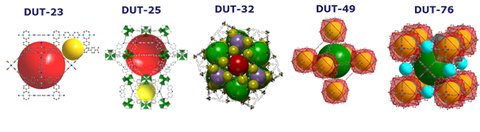

They offer the highest specific surface areas ever achieved (up to 7.000 m2/g!) and are ideal candidates for gas storage applications, gas purification (energy carriers such as hydrogen) and separation technologies. The group has developed numerous highly porous MOFs in recent years, termed DUT-n (DUT = Dresden University of Technology) ranging amongst record holders in terms of porosity and gas storage capability (Fig. 1).

Fig. 1: Selected MOF architectures discovered in Dresden (DUT = Dresden University of Technology)

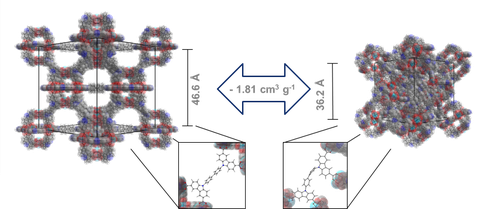

Some of them even show switchable porosity, a unique feature among porous materials. A new counterintuitive phenomenon recently discovered in DUT-49 is Negative Gas Adsorption (NGA, Fig. 2). The gas pushout during adsorption is a result of spontaneous compression into a narrow pore form of DUT-49..

Fig. 2: Pore contraction in the highly porous framework DUT-49

Links:

http://www.nature.com/nature/journal/v532/n7599/abs/nature17430.html

http://pubs.rsc.org/en/content/articlepdf/2014/CS/C4CS00101J

http://www.metal-organic-frameworks.eu/

http://eu.wiley.com/WileyCDA/WileyTitle/productCd-3527338748.html

b) Nanoporous Carbon Materials

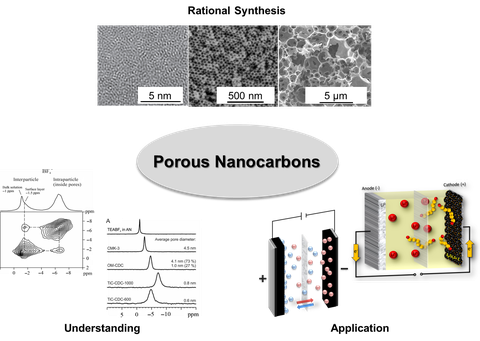

Lithium-Sulfur-Batteries represent the most promising next generation Lithium-Ion-Battery-Technology with up to 400 Wh/kg energy density surpassing traditional Li-Ion-Batteries by a factor more than 100 %. Supercapacitors offer extremely high power densities and high cycling stabilities (> 1 Mio. cycles) and are therefore used in energy recuperation (automobile, stationary). Both technologies require highly porous and functionalized carbons with well defined pore architecture. We develop hierarchical porous carbons and doped carbons for such applications.

Fig. 3: Pore size engineering of nanoporous carbons for supercaps and batteries

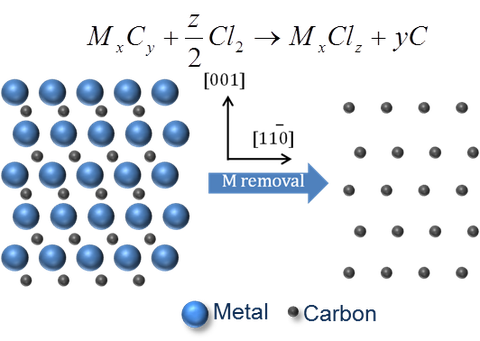

The understanding of adsorption processes in porous carbons is essential for improving the performance of porous carbons in various applications, for instance as electrode materials in electrochemical double-layer capacitors. For the investigation of such processes it is necessary to have a well-defined porosity. One way to synthesize microporous (pore size <2 nm) carbons with uniform pore size is the so-called carbide-derived carbon approach. Thereby metal or semimetal atoms are selectively etched out of a carbide matrix commonly using hot chlorine gas. Tuning of the carbide structure and the chlorination temperature allows adjusting pore sizes with high accuracy. (Fig. 4).

Fig. 4: Carbide-Derived-Carbon synthesis scheme

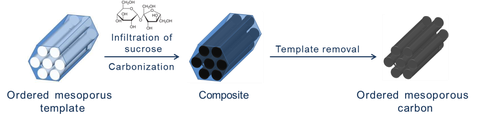

Larger well defined pore sizes in the meso (2—50 nm) or macropore (>50 nm) regime can be generated using the so called templating approach that can be divided in soft- and hard templating, also known as nanocasting. For hard templating, solid porous structures are infiltrated with a carbon precursor and are removed after carbonization took place, resulting in a negative replica structure. Depending on the pore structure of the template, a wide variation of pore size, pore connectivity and pore geometry is possible.

Fig. 5: Hard templating approach for mesoporous carbons

In the soft templating approach, amphiphilic structure directing agents (SDAs) serve as pore generating agents by forming micelles in solution. Adding a carbon precursor results in assembly around the SDA, followed by crosslinking of the precursors, thermal induced template removal and subsequent carbonization.

Links:

http://pubs.rsc.org/en/content/articlelanding/2014/mh/c3mh00112a#!divAbstract

http://onlinelibrary.wiley.com/doi/10.1002/anie.201409439/abstract

c) Perovskite Solar Cells

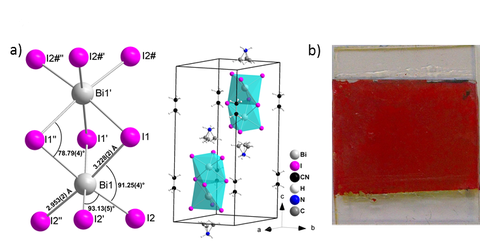

Solar cells are essential systems for light harvesting. New, cheap and easy to process absorber materials are a crucial for innovations and spreading of solar cell technology. We develop novel, solar cell absorber materials based on bismuth, to replace toxic lead in perovskite solar cells.

Fig. 6: Crystal structure of a new bismuth-based absorber material for solar cells ((MeNH3)3Bi2I9)

Link:

http://pubs.rsc.org/en/content/articlelanding/2016/cc/c5cc10455f#!divAbstract

Technologies and Applications (Energy Materials)

- Supercapacitor

- Lithium-Sulfur-Battery

- Electrocatalysis (HER, ORR, CO2 reduction)

- Electrode materials

- Electrochemical characterization

- Hydrogen storage

- Natural gas storage

- Gas purification

- O2/N2-Separation

- Heat storage (adsorptive)

- Catalytic combustion