Industrial Inorganic Chemistry

Table of contents

a) Catalytic Industrial Processes

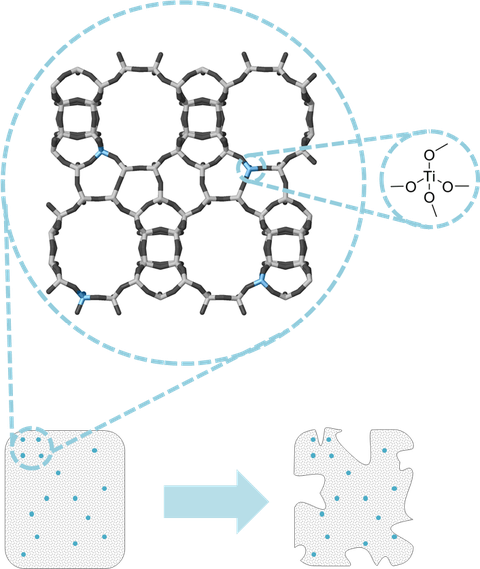

Zeolites and other porous materials are important heterogeneous catalysts for large scale industrial processes. Especially hierarchical zeolites offer a high selectivity combined with improved transport and deactivation characteristics. We develop new techniques for the synthesis of hierarchical zeolites for hydrocarbon conversion processes and oxidation catalysis.

Fig. 1: Ti-doped zeolite structure for oxidation catalysis

Technologies and applications

- Zeolites

- Methanol-to-Olefin process (MTO-Process)

- CO2 dry reforming

- High temperature catalysis

- Catalytic combustion

- Catalyst characterization and testing

Links

http://www.sciencedirect.com/science/article/pii/S1387181112002715

http://www.sciencedirect.com/science/article/pii/S1387181113006392

http://onlinelibrary.wiley.com/doi/10.1002/smll.201300906/abstract

b) Industrial separation/purification processes

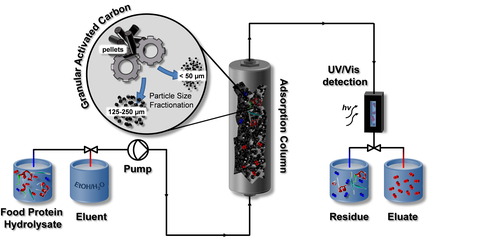

We develop materials and processes for adsorptive separation in industry. We evaluate porous materials and provide basic data to design larger processes for separation units in gas and liquid phase applications. Based on our knowledge and commercially available materials we select materials compatible with the scale and requirements of the separation application.

Fig. 2: Schematic representation of protein mixture separation for food chemistry applications

Technologies and applications

- N2/O2-separation

- Alkane/Alkene separation

- Hydrocarbon separation

- Noble gas separation

- Recovery of organics from water

- Adsorptive recovery of inorganic gases from streams

- Separation processes for food industry

Links

http://www.sciencedirect.com/science/article/pii/S0008622314004618?np=y

http://www.sciencedirect.com/science/article/pii/S0008622316304286

c) Industrial production of inorganic materials and chemicals

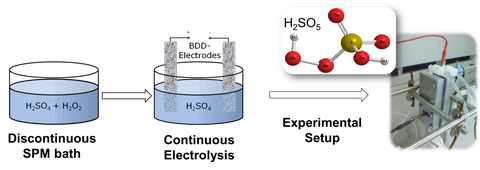

We develop production processes for industrial partners. We help to improve production processes. As an example, diamond electrodes were used for the continuous regeneration of peroxosulfuric acid for semiconductor industry (etching bath) in cooperation with Infineon using continuous electrooxidation.

Fig. 3: Scheme for the electrooxidation using diamond electrodes

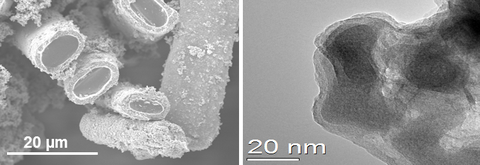

The development of coatings and surface functionalization for the integration of ceramic particles into metallic or polymer matrices can lead to transparent polymer nanocomposites or mixed-matrix composites for 3D printing and other applications. Core-shell systems are developed as customized formulations for example as rubber additives.

Fig. 4: Al2O3 fibers coated with copper (left) and Ni@SiO2 core-shell Particles (right)

Technologies and applications

- Nanoparticles, microparticles

- Particle coatings, surface functionalization

- Encapsulation

- Nanocomposites

- Ceramic materials

Links

http://www.sciencedirect.com/science/article/pii/S001346861401977X

http://www.sciencedirect.com/science/article/pii/B9780444533494002065

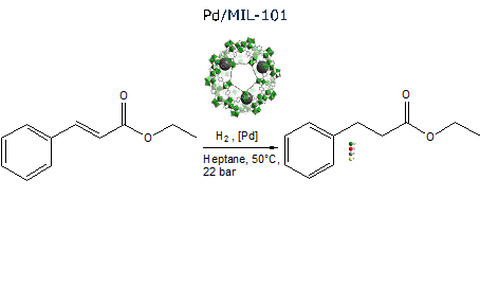

d) Fine chemicals

We develop novel materials for fine chemical production. Metal-Organic Frameworks and porous polymers offer a high degree of control over active sites for fine chemical transformations. We have developed MOFs and other porous materials for enantioselective aldol reactions, cyanosilylation, hydrogenation, and organocatalysis.

Fig. 5: MOF-catalyzed hydrogenation of cinnamic acid ester

Technologies and applications

- Aldol condensation catalyst

- Mukayama reaction catalyst

- Hydrogenation catalysts

- Oxidation catalysts

- Solid base catalysis

- Organocatalysis

Links

http://pubs.acs.org/doi/abs/10.1021/ja305482a

http://onlinelibrary.wiley.com/doi/10.1002/chem.201002568/suppinfo