Jul 03, 2019

Dresden start-up develops an innovative process for the production of electronic assemblies

The KONEKT team (left to right): Dr.-Ing. Andreas Krause (Technology Development); Dipl.-Ing. Sebastian Lüngen (Plant Engineering); M.Sc. Friedrich Hanzsch (Commercial Management); Dipl.-Ing. Tobias Tiedje (Technical Management)

At TU Dresden, packaging experts are not only found in mechanical engineering but also in other areas. Chips must be well encased so that they are protected from environmental influences. At the same time, the casing needs to be appropriate for contact with the outside world. Scientists from the Faculty of Electrical and Computer Engineering at TU Dresden have now developed a new technology which allows encasings and connections between components to be customised for their respective application.

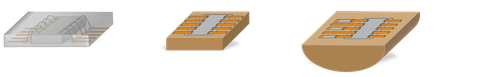

In the initial phase of this new development, the team, headed by Tobias Tiedje, research associate at TU Dresden’s Institute of Electronic Packaging Technology (IAVT) considered the reason as to why electronic components are always soldered onto a circuit board. Would it not be better to integrate the components directly into the chip casing? The scientists developed a manufacturing approach that required around half of the usual process and design steps, while at the same time tackling the current challenges of high data transmission, cooling and miniaturisation. The most diverse types of components and moulded parts as well as structures (cavities and microchannels) can be used. They call their new technology “Connecting Embedded Components as a Technology Solution”, KONEKT for short.

KONEKT revolutionises the production of electronic and micro-technical assemblies through the use of 3D manufacturing technology. The aim is to combine the advantages of mass production with the production of customised individual pieces. Simplified and automated processes enable optimised assemblies to be produced quickly by bonding the respective components so that they are suitable for high-frequency operation. At the same time, the process, energy and material costs are significantly reduced.

This gives medium-sized companies the opportunity to both establish new lines of business through rapid electronic manufacturing and to produce individual assemblies without high set-up costs. "With KONEKT, a wide variety of devices can be produced," explains KONEKT team leader Tobias Tiedje: "From 3D sensor assemblies as prototypes to RFID and high-frequency assemblies in series for the Internet of Things (IoT) – this novel technology offers users many possibilities in terms of design without limiting their creativity and innovation."

The KONEKT team, supported by dresden|exists, was able to raise 807,000 euro in funding from the Federal Ministry for Economic Affairs and Energy and the European Social Fund as part of the EXIST programme. The next step will be to establish it as a GmbH to enable the adaptive production of 3D assemblies in market-ready sizes and to offer small and medium-sized companies “packaging as a service.”

Media enquiries:

Dipl.-Ing. Sebastian Lüngen

Institute of Electronic Packaging Technology (IAVT)

Phone: +49 351 463-43790

konekt@avt.et.tu-dresden.de

www.avt.et.tu-dresden.de/konekt

Contact person for project management:

Dipl.-Ing. Tobias Tiedje

Phone: +49 351 463-32132

Contact person for plant engineering:

Dipl.-Ing. Sebastian Lüngen

Phone: +49 351 463-43790

Contact person for technology development:

Dr.-Ing. Andreas Krause

Phone: +49 351 463-43776

Contact person for commercial project management:

Friedrich Hanzsch, M.Sc.

Phone: +49 351 463-33007