Mircoscopy

Fields of application

Microscopy is an important component for the characterization of surfaces in material and material analysis. Just as in quality control and process development, image analysis is an integral part of life. With the aid of microscopy, one has the possibility to examine, analyze and evaluate surface structures in detail.

Microscopy is used for:

- the determination of the surface roughness (three-dimensional image position)

- the determination of the surface composition (particle determinations)

- the determination of surface damage (microcracks)

- the consideration of the formation of microcrackages (tensile modulus in the SEM)

- the analysis of coatings on surfaces

- the optical test of the surface quality.

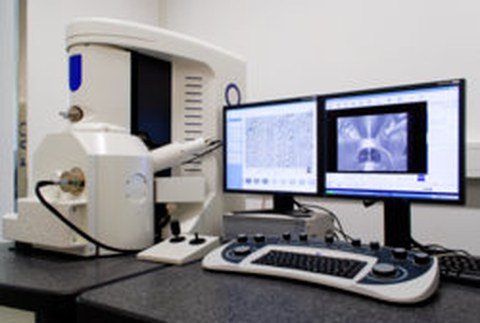

Methods

The scanning electron microscope (SEM) makes it possible to achieve a significantly higher magnification rate than a conventional light microscope by electron image formation. With this device, magnifications up to 200,000-fold are possible. Thus, insights into areas of the surface structure which are not possible with conventional means can be obtained. With the use of a micro-tensile module, the REM can show damage to tensile stresses, which may eventually lead to failure of the component. By means of the use of a vacuum diaphragm and thus the generation of a low vacuum in the sample chamber, plastics and nonmetals, which the electrons can not dissipate, can also be imaged very well.

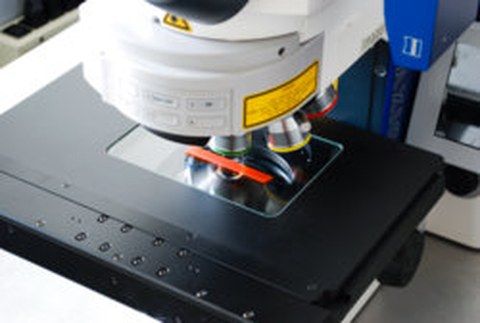

The laser scanning microscope (LSM) enables the image formation via a laser scanner with a wavelength of 405 nm, in addition to standard transmitted light / reflected light microscopy. As a result, high-resolution three-dimensional surface images with a resolution of 10 nm can be generated in the z-direction. Image processing software can be used to create mosaic and stack images in LSM mode as well as in light microscopy. The light microscope with a 6-fold turret with the help of the 5.0 MegaPixel camera takes pictures with a maximum magnification of 1000 x. The object table control is motorized and reproducibly reproducible up to 1 μm.

Digitalmikroskop Zeiss SmartZoom 5

Using the digital microscope, microscopic images can be examined and processed in real-time at up to 1000 times magnification. Due to the differentiated settings of the exposure (segmented LEDs or coaxial light field), surface structures with high depth depth can be examined in detail and 3D images can be generated. The integrated software allows the definition of a test sequence, which is repeated automatically for samples of the same type. In addition, composite images may be formed to accommodate a large area of the sample at high magnification. Within the microscopic images, measurements can be taken and texts can be added, even after completion of the recording.