C3-V4.19: Carbon reinforced parking slabs

Table of contents

Project data

|

Titel | Title |

Report in the annual report 2020

ORIGAMI WITH CARBON REINFORCEMENT

Folded carbon reinforcement to improve load-bearing behaviour

A major advantage of carbon reinforcement is its high resistance to chemical influences. Particularly in the case of large slabs, textile reinforcement leads to a more economical production compared with bar-shaped reinforcement. Parking garage ceiling slabs are exposed to chemical attack from de-icing salts, which is why carbon concrete can display all its advantages here. As part of the present project, parking garage ceiling slabs made of carbon concrete were therefore developed. To improve the load-bearing capacity – in particular, the composite load-bearing behaviour, as well as the shear load-bearing capacity – the reinforcement, was folded in the form of loops, within the support area of the slabs. But how effective are such loops and how can they be produced?

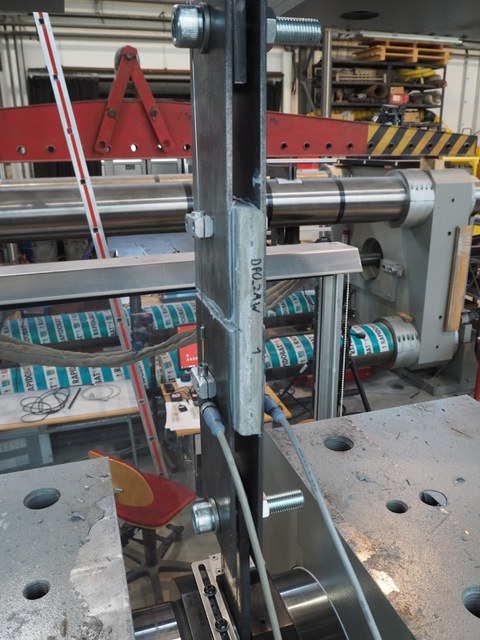

With the help of experimental investigations at the Institute of Concrete Structures, different constructions were designed to shorten the end anchorage length and to improve the shear force bearing capacity in the support area through loops. Four different reinforcement designs were subsequently manufactured in the Otto Mohr Laboratory of the TU Dresden for experimental investigations. The manufacture of the loops presented

a particular challenge. The conventionally available reinforcement textiles are impregnated and coated to improve the internal and external bond of the reinforcement. However, the impregnation and coating hinder the free forming of the reinforcement textile. For this reason, a reinforcement textile with a novel coating system was used.

When heated, the stiffness of the textile is reduced, making it soft and malleable. After cooling, the coating system hardens so that the textile retains its shape and regains its original internal and external composite properties. This new technology overcame a major hurdle to producing curved coated reinforcing textiles.

The loops formed in this way replaced the straight anchorage length in the reinforcement used for the fabrication of 9 cm thick concrete slabs. The test elements were produced at the facilities of the project partner Dressler Bau GmbH and later tested at the OML using a four-point bending test. A positive effect of the loops on the shear force bearing behaviour was demonstrated. Further manufacturing methods are to be investigated and validated in the course of the project.

Report in the annual report 2019

CARBON CONCRETE CEILING SLABS

Model of a carbon loop

The use of carbon reinforcement is intended to increase the durability and cost-effectiveness of heavily stressed ceiling slabs. Particularly in the case of multi-storey car park ceiling slabs, the components are subjected to strong mechanical and chemical effects. A significant chemical effect is caused by chloride-containing de-icing agents to which the ceiling slabs are exposed, especially in winter. From both a technical and economic point of view, the use of carbon reinforcement promises a great advantage in this application. The ceiling slabs are usually fixed to supporting beams with a relatively small depth. It is, therefore, necessary to anchor the reinforcement within a short length. Therefore, an optimized end anchoring solution has to be developed within the scope of this project. Furthermore, there is a risk of shear force failure. This can also be counteracted by a suitable end anchorage solution.

The Institute of Concrete Structures is dealing with several aspects of this project. First, a preliminary geometry and material selection of the concrete mix and the reinforcement of the ceiling was carried out. This selection was validated by experimental investigations. With the help of material tests, the load-bearing and composite behaviour of this preferred solution were quantified. Trough computer-aided programs the resonance behaviour of the planned slabs was investigated.

Experimental investigation of the bond load-bearing capacity

In addition, different loop concepts for the final anchoring of the reinforcement were developed. They will be evaluated in the next step by means of experimental investigations. In particular, their effect on the bond length as well as their effect on the shear force bearing behaviour will be investigated. An important aspect in the design of the anchoring, apart from the pure load-bearing capacity, is the necessity of an economically reasonable production and installation. In the further course, these end anchorage solutions are to be transferred to a large component and validated by means of a large component test.

Report in the annual report 2018

THE PERFECT APPLICATION FOR CARBON REINFORCED CONCRETE?

Großbauteilversuch zur Untersuchung der Endverankerung der Carbonbewehrung

Steel reinforced concrete has a variety of positive properties, which is why it is the most common used material in the world today. However, reinforced concrete components have the significant disadvantage that the steel reinforcement in the component corrodes over time. This problem intensifies for components permanently exposed to strong media or environmental influences. A typical example for this are parking garage slabs. These are usually made of reinforced concrete and show considerable damage or defects due to durability problems of the steel reinforcement after a short period of time. Therefore, parking garage slabs are usually provided with expensive and high-maintenance coating systems to minimise durability problems. However, this is not the optimal solution, which is why the project C3-V4.19 pursues an alternative strategy for multi-storey car parks: corrosion-resistant and high-performance carbon reinforcement in form of webs to replace the corrosive steel reinforcement. The outcome are parking garage slabs made of carbon reinforced concrete that are durable and, at best, maintenance-free due to the corrosion resistance of the carbon fibres.

Tastversuch zur Überprüfung der gewählten Materialkombination

To smooth their way into practice, essential questions need to be answered. In this special case, the composite behaviour and the end-anchoring behaviour of the chosen carbon reinforcement is examined for short support lengths, since parking garage slabs usually have only small bearing widths. The bond behaviour is studied on small-scale experiments as well as on large-scale components. First tentative tests with selected material combinations, using a recently developed carbon grid, have already been carried out and demonstrated a high performance.

Using those first findings, further small-scale tests will be carried out in order to characterise the bond behaviour of the new carbon grid. Subsequently, large-scale slabs will be produced and tested to prove the suitability of carbon reinforced concrete slabs for short bearing widths.