C3-B1: Coatings and reinforcements for carbon concrete construction

Table of contents

Project data

| Titel | Title TP C3-B1-I-c: Anforderungen an Bewehrungsstrukturen sowie Untersuchungen zum Verbundverhalten zwischen Textil und Beton als Teilvorhaben im Basisvorhaben C3-B1: Beschichtungen und Bewehrungsstrukturen für den Carbonbetonbau | TP C3-B1-1a-I-c: Requirements on reinforcement structures and studies of the bond behaviour between textile and concrete as part of the basic project C3-B1: Coatings and reinforcement structures for carbon concrete constructions. Förderer | Funding Bundesministerium für Bildung und Forschung (BMBF); Projektträger: PT Jülich / C3 – Carbon Concrete Composite Zeitraum | Period 05.2015 – 01.2017 Leiter | Project Manager Prof. Dr.-Ing. Dr.-Ing. E.h. Manfred Curbach Bearbeiter | Contributor Dipl.-Ing. (FH) Frank Neumann Projektpartner | Project Partners 15 Partner, darunter 5 Forschungseinrichtungen und 10 Unternehmen |

Report in the year book 2016

Bond between carbon and matrix

Cross section of an unevenly impregnated carbon roving. The gray areas are accumulations of the polymer impregnation what results in increased water absorption

As an alternative to common steel reinforcements, carbon fibre reinforcements have been investigated for many years. This type of reinforcement is resistant to corrosion, more durable, and it has a higher load-bearing capacity than that of steel. Fibre bundles made of thousands of filaments are called rovings. From these rovings, textile grids are produced and coated, often with a polymer matrix, to ensure and optimize the load transfer between textile grids and concrete. But the interaction between the two components, carbon, and concrete, is mostly unknown and remains a key research issue. Of particular interests to current research efforts are the bond behavior between the single filaments, the roving and the polymer matrix as well as between polymer matrix and concrete.

As of now, some parameters influencing the bond-behaviour between carbon fibers with a polymer coating and the concrete have already been identified. These include the chemical composition of the coating, the local and global geometry of the cross-section areas, the mesh size and the local or global undulation due to the production process of the rovings and grids. Within the C3 basic project C3-B1, the bond behavior of carbon reinforced concrete is investigated at temperatures between 20 °C and 80 °C. As a result, additional factors influencing the bond behavior were identified. Besides the glass transition temperature of polymer coatings, the water absorption capacity of carbon grids influences the bond behaviour. If the class transition temperature is lower than the expected or applied temperature, coatings are getting soft and the bond between coating and concrete will be reduced significantly. As a direct consequence of this, the roving will be pulled out of the concrete under tensile load.

The water absorption capacity of the carbon grid directly influences the growth of the so-called calcium silicate hydrate phases. In addition to other well-known effects caused by reduced w/c-ratio, the lack of water within the bond zone increases the growth of portlandite. The loss of water, within the vicinity of fresh concrete surrounding the rovings, namely the bond zone, depends on the capillarity or permeability of the textile grids. The smaller the spacing of the rovings, or mesh size, the higher is the loss of water. Keeping this effect in mind, the w/c-ratio shall be optimized, especially in-between the bond zone, which means the interphase between concrete and polymer coating. Such a consideration is of tremendous importance to ensure a high strength bond behaviour.

Report in the year book 2015

New requirements on carbon reinforcements

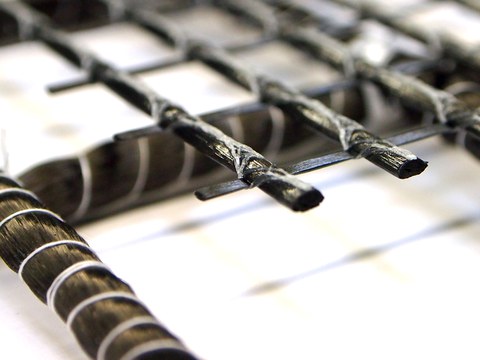

Conventional carbon reinforcement (lying above) and prototypical Carbon reinforcement of larger cross section (below)

In common research and application projects, rovings with a diameter between 1 and 3 mm are used. Those rovings usually consist of between 12,000 and 50,000 filaments. In case of high stress values, roving cross-sections have to be increased, as it is commonly done with regular steel rebars in reinforced concrete. As one part of the joint research project C3, the project B1 “Coatings and reinforcement structures for carbon concrete constructions” started in 2015. The scope of the basic project B1 is the production and analysis of rovings and rods containing more than 50,000 filaments. The cross-section of carbon fibre reinforcements may be adjusted in two ways: by increasing or decreasing the number of filaments or by changing the roving centre distances in either one or both grid directions. Within B1, rovings consisting of up to 8 times 50,000 filaments will be produced. Their material properties and their applicability as a reinforcement in concrete will then be tested.

Nowadays, machines for textile reinforcement production cannot, or only with significant restrictions, deal with a quantity of filaments greater than 2 times 50,000. This is why main machine parts have to be adjusted. Depending on production and coating technology, cross-section’s shape may vary between flat, round, oval and elliptic. The shape especially influences the mechanical properties of carbon concrete as a multicomponent system. In addition to that, one or more new coatings will be developed. As carbon concrete is a multicomponent system, it is necessary to examine every single material property.

The focus within C3 is the development of new construction forms. One task within B1 is to define specific requirements e.g. of shape, centre distance, roving direction, minimum concrete cover and anchorage length. From there, questions about serviceability and durability throughout the lifecycle of carbon concrete constructions have to be answered. Main indications thereof can be found by researching bond, creep and temperature behaviour.