Carbonbeton (CRC) - Forschung

Inhaltsverzeichnis

- C - 30 Vier-Punkt-Biegeversuch an einem T-Balken aus Carbonbeton

- C - 29 Biegetragverhalten von selbstvorgespannten Betonplatten mit Carbonstabbewehrung

- C - 28 Alternierende Bewehrungsführung in Dehnkörperversuchen

- C - 25 Carbonbeton unter zweiaxialer Zugbelastung

- C - 5 Einbauteile für Bauteile aus Carbonbeton

- C - 2 Vorgespannte Bewehrungen aus Carbon, Glas und Basalt

C - 30 Vier-Punkt-Biegeversuch an einem T-Balken aus Carbonbeton

*Projektarbeit/Diplomarbeit - Versuchsplanung und Untersuchung der Tragfähigkeit von filigranen Carbonbetonbalken

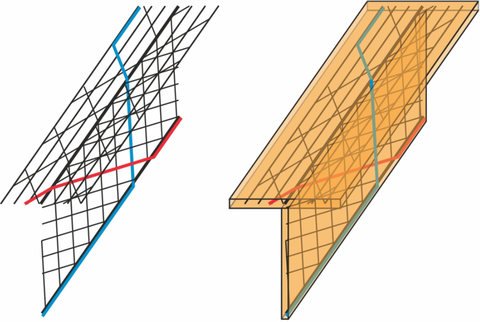

Bewehrungsführung der alternierenden Carbonbewehrung

Aufbauend auf einer derzeit laufenden Projektarbeit, bei der die Bewehrungsführung für einen filigranen Carbonbetonbalken untersucht wurde, soll die hergestellte Bewehrung in einem 4-Punktbiegeversuch auf ihre Tragfähigkeit untersucht werden. Die Besonderheit liegt in den dünnen Querschnittskomponenten. Da Carbonbewehrung anders als Stahl nicht korrodieren kann, wird nur eine sehr geringe Betondeckung notwendig. In einem konventionellen Stahlbetonbalken umschließen die Bügel zur Aufnahme der Querkraft die Längsbewehrung zur Aufnahme der Zugkräfte. Bei Stegen von nur 3 cm, ist eine Bügelbewehrung nicht realisierbar, daher wird die Bewehrung der Carbongarne alternierend ausgeführt. Das Prinzip der alternierenden Bewehrungsführung wurde am Institut bereits in Vorgängerprojekten entwickelt (Beispiel siehe: Netzgitterträger).

*Je nachdem, ob eine Projekt- oder Diplomarbeit angefertigt wird, kann der Umfang nur die Versuchsplanung beinhalten, oder für Zweiteres die Ausrichtung der Tragfähigkeitsanalyse eingegrenzt werden.

Die Aufgabenstellung wird in Absprache mit der Studentin/dem Studenten konkretisiert.

Ansprechpartnerin:

Dipl.-Ing. Lore Zierul

0351 463 33609

C - 29 Biegetragverhalten von selbstvorgespannten Betonplatten mit Carbonstabbewehrung

Bearbeitung nur im Rahmen einer Masterarbeit möglich

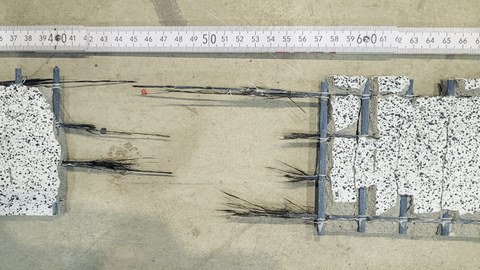

Untersuchung der Verbundentwicklung zwischen Beton und Carbonbewehrungsstäben

Carbonbewehrungsstäbe werden zunehmend als Alternative zur konventionellen Stahlbewehrung eingesetzt, häufig in Kombination mit hochfestem Beton. Dieser weist jedoch eine erhöhte Schwindneigung auf, die zu Rissbildung und weiteren Gebrauchstauglichkeitsproblemen führen kann. Aufgrund ihrer geringen Druckfestigkeit sind Carbonbewehrungsstäbe nur eingeschränkt in der Lage, negative Schwinddehnungen aufzunehmen. Infolgedessen kann die Bewehrung in einen passiven Zustand übergehen, wodurch ihre Wirksamkeit und das Tragverhalten des Bauteils beeinträchtigt werden.

Ziel dieser Arbeit ist es daher, den Einfluss von Quellbeton auf das Tragverhalten von mit Carbonbewehrungsstäben bewehrten Betonplatten zu untersuchen. Durch eine kontrollierte Volumenzunahme soll der Quellbeton Schwindverformungen teilweise oder vollständig kompensieren. Bei ausreichender Verbundwirkung zwischen Beton und Carbonbewehrungsstäben kann diese Expansion zudem Zugdehnungen in den Stäben induzieren, wodurch Zugspannungen entstehen und die Carbonbewehrung aktiviert wird. Insgesamt wird erwartet, dass der Einsatz von Quellbeton das Rissverhalten verbessert und die Durchbiegungen der Platten signifikant reduziert.

Zur Umsetzung dieses Forschungsvorhabens werden mehrere Betonplatten aus Quellbeton mit Abmessungen von etwa 1500 mm × 500 mm × 80 mm hergestellt. Vorab erfolgen Versuche an kleinmaßstäblichen Probekörpern zur Untersuchung der Verbundentwicklung zwischen Beton und Carbonbewehrungsstäben. Zur Erfassung der Ausdehnungen sowie der Dehnungen im Beton und in den Bewehrungsstäben kommt die Technologie verteilter faseroptischer Sensoren (Distributed Fiber Optic Sensing, DFOS) zum Einsatz.

Ansprechpartner:

Mohammed Dhahir M.Sc.

+49 351 463-40411

Jasmin Dräger M.Eng.

+49 351 463-39878

C - 28 Alternierende Bewehrungsführung in Dehnkörperversuchen

Projekttarbeit: Konzeptionierung von Versuchen

Herkömmlicher Dehnkörperversuch

Bauteile können dünner hergestellt werden, wenn Carbonbewehrung verwendet wird, da nur eine sehr geringe Betondeckung notwendig wird. Damit einhergehend ist das Bauen durch assemblierte Plattenelemente statt durch die Verwendung von Vollquerschnitten. Die Querkraftbewehrung kann dann allerdings nicht furch Bügel realisiert werden, was zu dem Konzept der alternierenden Bewehrungsführung überleitet (Beispiel siehe: Netzgitterträger). Bestehende Richtlinien geben Vorgaben über die Durchführung von Versuchen mit geradem Gitter.

In der Arbeit soll in Zusammenarbeit mit dem Institut für Textilmaschinen und textile Hochleistungswerkstofftechnik Versuchsaufbauten für die Bestimmung von Verbundeigenschaften recherchiert und ein Aufbau umgesetzt werden.

Die Aufgabenstellung wird in Absprache mit der Studentin/dem Studenten konkretisiert.

Ansprechpartnerin:

Dipl.-Ing. Lore Zierul

+49 351 463-33609

C - 25 Carbonbeton unter zweiaxialer Zugbelastung

Trag- und Verformungsverhalten von Carbonbeton unter zweiaxialer Zugbelastung

Platten aus Carbonbeton zeigen hygrische und temperaturbedingte Verformungen in zwei senkrecht zueinanderstehenden Richtungen. Diese führen zu zweiaxialen Spannungen in der Platte. Tritt eine zweiaxiale Zugspannung auf, resultiert dies in Rissen des Betons bis hin zum Garnbruch. Infolge der gegenseitigen Beeinflussung der beiden Belastungsrichtungen weicht das Trag- und Verformungsverhalten der Platten aus Carbonbeton von einaxialen Zugversuchen ab.

In dieser Arbeit sollen Platten aus Carbonbeton unter zweiaxialer Zugbelastung experimentell untersucht werden. Zu diesem Zweck werden zunächst die Ergebnisse bereits vorhandener Forschungsarbeiten zu Textil- und Carbonbeton unter zweiaxialer Zugbelastung zusammengefasst und gegenübergestellt. Im Anschluss werden experimentelle Untersuchungen an Platten aus Carbonbeton durchgeführt, ausgewertet und mit den Erkenntnissen aus der Literaturrecherche verglichen. Ziel ist die Charakterisierung des Trag- und Verformungsverhaltens von Carbonbeton unter zweiaxialer Zugbelastung.

Die Aufgabenstellung wird in Absprache mit der Studentin/dem Studenten konkretisiert.

Ansprechpartner:

Dipl.-Ing. Jonathan Schmidt

0351 463 41118

C - 5 Einbauteile für Bauteile aus Carbonbeton

* nur in deutscher Sprache *

Bei der Verwendung von Carbonbewehrung im Fertigteilbau kann eine Reduzierung der Bauteilstärken auf wenige Zentimeter erfolgen. Die klassische Verbindungstechnik setzt auf massive Bauteile, die als ungestörter Ankergrund dienen. Die geringe Bauteilstärke im Carbonbetonbau und die damit einhergehende erhöhte Wahrscheinlichkeit der Rissbildung stellen neue Anforderungen an die Befestigungssysteme. Systeme wie beispielsweise der Halfen Fassadenplatter Anker FTA-3 passen sich den neuen Herausforderungen an.

In der Arbeit sollen Methoden gesammelt und bewertet werden, die eine punktförmige Lasteinleitung in Carbonbeton durch eine räumliche Verteilung günstiger für den Ankergrund gestalten können, um damit zum einen der geringen Bauteilstärke als auch der erwartbaren Rissbildung zu begegnen. Diese Methoden sollen zu Produktkonzepten weiterentwickelt werden. Die prinzipiellen Potentiale der Lastabtragung sind abzuschätzen. Zur Analyse der Lastabtragung können FE-Programme zur Anwendung kommen. Es ist aber auch eine Bearbeitung ohne EDV-Unterstützung, beispielsweise durch Anwenden von Stabwerkmodellen, möglich. Details der Aufgabe werden gemeinsam mit der Studentin bzw. dem Studenten festgelegt.

* Kenntnisse in der Befestigungstechnik werden vorausgesetzt *

Ansprechpartner:

Dr.-Ing. Harald Michler

0351 463 32550

C - 2 Vorgespannte Bewehrungen aus Carbon, Glas und Basalt

Ausführlicher Titel: Möglichkeiten und Randbedingungen für die Herstellung und den Einsatz von vorgespannten textilen Bewehrungen

* nur in deutscher Sprache *

Bislang werden nichtmetallische Bewehrungen hauptsächlich als schlaffe Bewehrung eingesetzt. Mittlerweile sind aber bereits auch Möglichkeiten der Vorspannung wie vorfabrizierte vorgespannte Platten (CPC-Platten) am Markt. Die Arbeit soll aktuelle Anwendungen für vorgespannte nichtmetallische Bewehrungen – meist im Rahmen von Forschungsprojekten – sammeln und analysieren. Eine vergleichende Betrachtung der Materialeigenschaften von metallsichen und nichtmetallischen Vorspannbewehrungen soll dabei das Potential der einzelnen Materialien abschätzen, beispielsweise die Auswirkungen der Relaxation. Dabei sind die verschiedenen Methoden der Vorspannung, wie Vorspannung mit sofortigem, nachträglichem oder ohne Verbund, einzeln zu betrachten.

Die Arbeit beinhaltet ein Literaturstudium und vorzugweise vergleichende Handrechnungen. Details der Aufgabe werden gemeinsam mit der Studentin bzw. dem Studenten festgelegt.

Ansprechpartner:

Dr.-Ing. Harald Michler

0351 463 32550