Carbon-reinforced concrete (CRC) - research

Table of contents

- C - 30 Four-point bending test on a T-beam made of carbon reinforced concrete

- C - 29 Flexural behavior of self-prestressed concrete slabs with carbon rod reinforcement

- C - 28 Alternating reinforcement guidance in expansion body tests

- C - 25 Carbon concrete under biaxial tensile load

- C - 5 Installation parts for components made of carbon concrete

- C - 2 Prestressed reinforcements made of carbon, glass and basalt

C - 30 Four-point bending test on a T-beam made of carbon reinforced concrete

*Projectwork/Masterthesis - Planning of test-setup and load-bearing behaviour of filigree carbon concrete beams

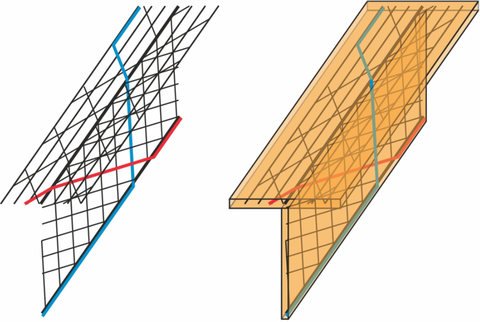

Placement for alternating carbon reinforcement

Based on ongoing project work investigating the reinforcement layout for a filigree carbon concrete beam, the manufactured reinforcement is to be tested for its load-bearing capacity in a 4-point bending test. The special feature lies in the thin cross-section components. Since carbon reinforcement, unlike steel, cannot corrode, only a very thin concrete cover is necessary. In a conventional reinforced concrete beam, the stirrups for absorbing shear forces enclose the longitudinal reinforcement for absorbing tensile forces. With webs of only 3 cm, stirrup reinforcement is not feasible, so the carbon yarn reinforcement is designed alternately. The principle of alternating reinforcement has already been developed at the institute in previous projects (see example: textile lattice girder).

*Depending on whether a project or thesis is being written, the scope may only include the experimental design, or, in the latter case, the focus of the load-bearing capacity analysis may be narrowed down.

The task will be specified in consultation with the student.

Contact person:

Dipl.-Ing. Lore Zierul

0351 463 33609

C - 29 Flexural behavior of self-prestressed concrete slabs with carbon rod reinforcement

Processing only possible as part of a master's thesis

Investigation of composite development between concrete and carbon reinforcement bars

Carbon reinforcing bars are increasingly being used as an alternative to conventional steel reinforcement, often in combination with high-strength concrete. However, this has an increased tendency to shrink, which can lead to cracking and other serviceability problems. Due to their low compressive strength, carbon reinforcement bars are only able to absorb negative shrinkage strains to a limited extent. As a result, the reinforcement can go into a passive state, which impairs its effectiveness and the structural behavior of the component.

The aim of this work is therefore to investigate the influence of swelling concrete on the load-bearing behavior of concrete slabs reinforced with carbon reinforcement bars. The swelling concrete should partially or completely compensate for shrinkage deformations through a controlled increase in volume. If there is sufficient bonding between the concrete and the carbon reinforcement bars, this expansion can also induce tensile strains in the bars, causing tensile stresses and activating the carbon reinforcement. Overall, the use of swelling concrete is expected to improve the cracking behavior and significantly reduce the deflections of the slabs.

To implement this research project, several concrete slabs made of swelling concrete with dimensions of around 1500 mm × 500 mm × 80 mm will be produced. Prior to this, tests are carried out on small-scale test specimens to investigate the bond development between concrete and carbon reinforcement bars. Distributed fiber optic sensing (DFOS) technology is used to record the expansions and strains in the concrete and the reinforcing bars.

Contact person:

Mohammed Dhahir M.Sc.

+49 351 463-40411

Jasmin Dräger M.Eng.

+49 351 463-39878

C - 28 Alternating reinforcement guidance in expansion body tests

Project work: Conceptual design of tests

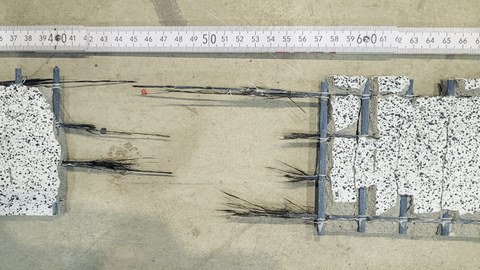

Herkömmlicher Dehnkörperversuch

Components can be manufactured thinner if carbon reinforcement is used, as only a very small concrete cover is required. This is accompanied by construction using assembled slab elements instead of full cross-sections. However, the shear force reinforcement cannot then be realized using stirrups, which leads to the concept of alternating reinforcement routing (for an example, see: mesh lattice girders). Existing guidelines provide specifications for carrying out tests with a straight grid.

In the thesis, in cooperation with the Institute of Textile Machinery and High Performance Material Technology, test setups for the determination of composite properties are to be researched and a setup implemented.

The task will be specified in consultation with the student.

Contact person:

Dipl.-Ing. Lore Zierul

+49 351 463-33609

C - 25 Carbon concrete under biaxial tensile load

Load-bearing and deformation behavior of carbon concrete under biaxial tensile loading

Carbon concrete slabs exhibit hygric and temperature-induced deformations in two perpendicular directions. These lead to biaxial stresses in the slab. If a biaxial tensile stress occurs, this results in cracks in the concrete up to yarn breakage. As a result of the mutual influence of the two load directions, the load-bearing and deformation behavior of carbon concrete slabs deviates from uniaxial tensile tests.

In this work, carbon concrete slabs are to be experimentally investigated under biaxial tensile loading. For this purpose, the results of existing research work on textile and carbon concrete under biaxial tensile loading are first summarized and compared. Subsequently, experimental investigations on slabs made of carbon concrete are carried out, evaluated and compared with the findings from the literature research. The aim is to characterize the load-bearing and deformation behavior of carbon concrete under biaxial tensile loading.

The task will be specified in consultation with the student.

Contact person:

Dipl.-Ing. Jonathan Schmidt

0351 463 41118

C - 5 Installation parts for components made of carbon concrete

* only in German language *

When using carbon reinforcement in precast construction, component thicknesses can be reduced to just a few centimetres. The classic connection technique relies on solid components that serve as an undisturbed anchor base. The low component thickness in carbon concrete construction and the associated increased probability of cracking place new demands on the fastening systems. Systems such as the Halfen Fassadenplatter Anchor FTA-3 adapt to the new challenges.

The aim of the work is to collect and evaluate methods that can make point load application in carbon concrete more favorable for the anchor base through spatial distribution in order to counteract both the low component thickness and the expected crack formation. These methods are to be further developed into product concepts. The principle potentials of load transfer are to be estimated. FE programs can be used to analyze the load transfer. However, it is also possible to work without computer support, for example by using framework models. Details of the task are determined together with the student.

* Knowledge of fastening technology is assumed *

Contact person:

Dr.-Ing. Harald Michler

0351 463 32550

Harald.Michler@tu-dresden.de

C - 2 Prestressed reinforcements made of carbon, glass and basalt

Detailed title: Possibilities and boundary conditions for the production and use of prestressed textile reinforcements

* only in German language *

Up to now, non-metallic reinforcements have mainly been used as slack reinforcement. In the meantime, however, prestressing options such as prefabricated prestressed plates (CPC plates) are already on the market. The work is intended to collect and analyze current applications for prestressed non-metallic reinforcements - mostly in the context of research projects. A comparative analysis of the material properties of metallic and non-metallic prestressing reinforcements is intended to assess the potential of the individual materials, for example the effects of relaxation. The different methods of prestressing, such as prestressing with immediate, subsequent or without bond, are to be considered individually.

The work includes a literature study and preferably comparative hand calculations. Details of the task will be determined together with the student.

Contact person:

Dr.-Ing. Harald Michler

0351 463 32550