Jan 24, 2023

The future of robotics is soft and tactile – TUD startup teaches robots to feel

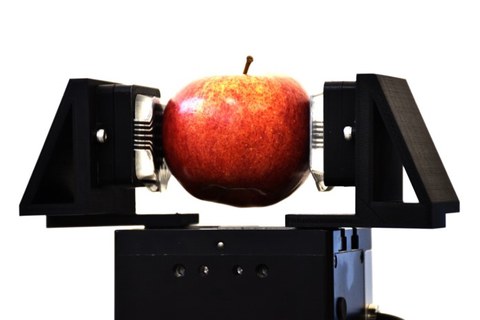

TouchDetect von PowerOn

Robotics has evolved at an unprecedented rate over the past several decades. Yet many robots remain inflexible, cumbersome and noisy. Now, the TU Dresden spin-off PowerON seeks to change that. It aims to break down the barrier between humans and robots. The next generation of robotics will feature sensory skins, fabricated muscles and artificial neurons printed on flexible materials, opening up new fields of application. “We’re observing a drastic upward trend in automation across all areas of industry and will soon see more of this in our everyday life,” says Dr. Markus Henke, Junior Research Group Leader at TU Dresden’s Institute of Semiconductors and Microsystems and co-founder of PowerON.

The start-up uses the results of collaborative research conducted by TU Dresden and the University of Auckland in New Zealand, where Markus Henke completed a two-year postdoc fellowship after having earned his doctorate at our own Faculty of Electrical and Computer Engineering. In close cooperation with TU Dresden, he and the local team explored the scientific foundations of multifunctional dielectric elastomers in soft robotics as part of a Marie Curie Fellowship awarded by the European Commission. Upon his return to TU Dresden, he and his colleagues founded PowerON with the help and support of the dresden | exists start-up service and funding from a start-up grant. In addition, Dr. Markus Henke was able to acquire an Emmy Noether Junior Research Group at the Chair of Microsystems, which studied the foundations of bioinspired robotics based on dielectric elastomers.

“Once the technology is advanced enough, we expect to encounter robots not just in industry, but also in our daily lives.” To this end, the PowerON team wants to use its very first product – a type of sensory fingertip for industrial robots – to substantially expand on robots’ fields of application and allow conventional robot grippers to perform more delicate tasks. These could prove useful for handling fragile items such as eggs or test tubes, removing rubber products from injection molds, harvesting fruits and vegetables, or even being implemented at home and in medical care. With a view to the decreasing number of skilled workers, researchers see great potential in this area. The initial practical tests are set to begin in the coming weeks. The first demonstrator to exhibit the interplay of touch-sensitive skin, manufactured muscles and artificial neurons has already been completed. It is a gripper that is exclusively powered by artificial muscles, which are in turn controlled by artificial neurons. The gripper itself is a 3D print of flexible materials, does not feature any conventional joints and is equipped with a tactile skin that can feel how and where an object was gripped.

PowerON works closely with TU Dresden and is a partner in the large-scale research project “6G-life.” “This partnership is a testament to the cooperation potential between science and industry and how such collaborative projects can contribute to quickly transferring scientific findings into commercial products,” says Prof. Andreas Richter, Chair of Microsystems and Director of the Institute of Semiconductors and Microsystems.

Video

The demonstrator was introduced at the first SAXONY! TechTalks on December 6, 2022, in cooperation with the Saxony Trade & Invest Corporation. You can view a recording of the event on YouTube: https://youtu.be/aFgCMhPWjXc

PowerON spin-off: https://www.poweron.one

Contact

Dr.-Ing. E.-F. Markus Henke

Tel: +49 351 - 463-39962

Email: