Education and Research Power Plant in the Centre for Energy Technology

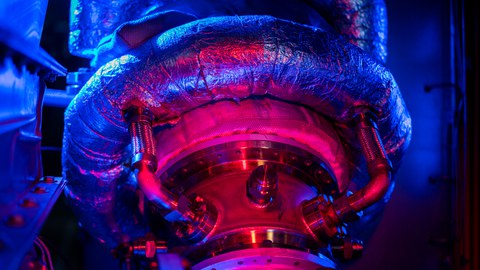

Steam-injected gas turbine with water recovery

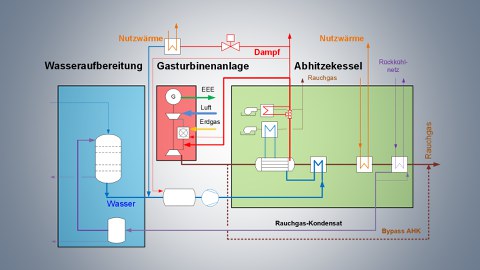

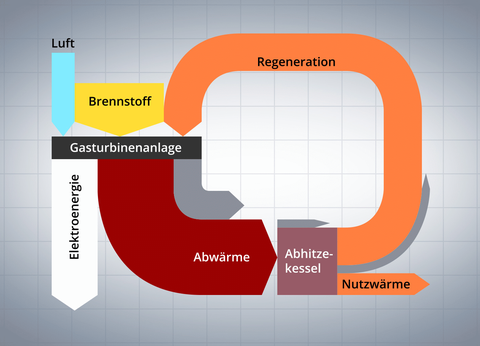

The facility displays a steam injected gas turbine plant in a semi-open construction, that is, with recovery of process water. As opposed to a combined gas and steam turbine plant, this facility can generate the desired electroenergy with minimal useful heat submission by returning superfluous waste heat regeneratively to the gas turbine in the form of steam. In partial load operations (in terms of the useful heat submission) fuel can thus be saved at full mechanical power, the economic efficiency can be increased and heat emissions into the environment can be minimized.

Prozessschema ZET-Kraftwerk

- Demonstration of power station processes

- Steam injection for high steam mass flow (optimal position, optimal steam parameters, mixing with flue gas)

- Influence on flow, cooling, behavior and lifetime of the turbine

- Influence on behavior and performance of the compressor

- Water processing (process, operations at increased temperatures )

Energieflussdiagramm des GiD-Prozesses

The experimental power station is supervised by the Chair of Thermal Power Machinery and Plants

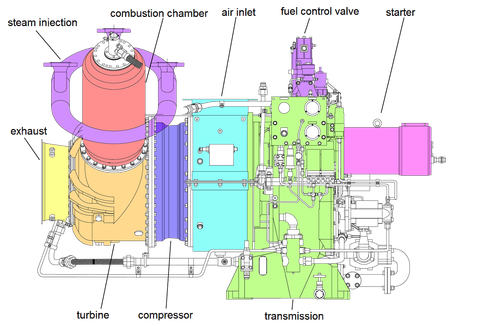

The gas turbine of type GPB06plus is the core of the plant.

Technical Specifications:

- Elektrical output Pel=650 kW

- Pressure ratio Π=9

- Turbines inlet temperature tinlet=910°C

- Turbines exhaust temperature toutlet=480°C

- Compressors mass flow mVerdichter=5kg/s

- Two-stage radial compressor

- Natural gas-fired silo combustion chamber with steam injection equipment

- Three-stage axial turbine uncooled

- Steam injektion for NOX reduction (mD_NoX=0,3t/h)

- Additional steam injection (mD=1,7t/h)

commissioningS:

- 2011 April 30., 12:13: first fire, operation with bypass

- 2011 May 18., 16:45 : first synchronization with local grid

- 2011 June 29.: Evidence of performance and fuel consumption in operation without steam injection

- 2012 February 12: test of steam injection into the turbine with superheated steam

- 2012 April 17.-19.: 48h-continuous operation with saturated steam, test the operation mode with PLUS-steam injection

- 2012. April 20.: Assumption of turbine, operation by TU Dresden

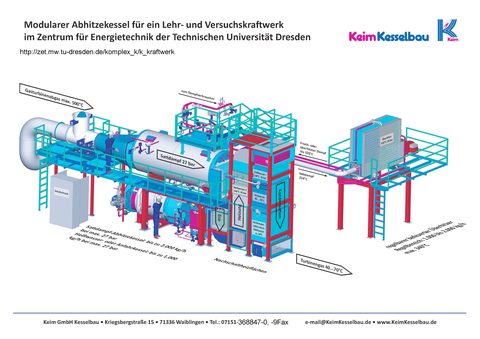

The multi-part heat recovery steam generator uses the waste heat of the gas turbine. It is designed for operation with varying flue gas composition and has an additional gas-fired superheater and a burner for simulating of extraneous heat entry. In its last stage, it is possible to condense water from the flue gas and thus regain for the cycle.

technical specifications:

- pressure of steam pDampf=24bar(e)

- life steam temperature tDampf=230°C-340°C

- Separate superheater 180kW

- additional burner 800kW

- District heat extraction (130°C-85°C)

- Heat extraction (80°C-60°C)

- Flue gas condensator

Ansicht Kessel

commissinings:

- 2011 November 15.: first firing of the hot gas generator with vapor production to maximum pressure

- 2011 November 29.: commissioning of the steam cycle (boilers, steam reduction, heating capacitor, buffer) and blowing out the steam line to the gas turbine

- 2011 November 30.: commissioning of the water quality assurance system of the steam cycle

- 2011 December 13.: first steam generation by gas turbine and district heating

- 2012 February 12.: Acceptance of the boiler, operation by TUD

Schema Kessel