Oct 07, 2025

Launch of the "BiPWalz" project

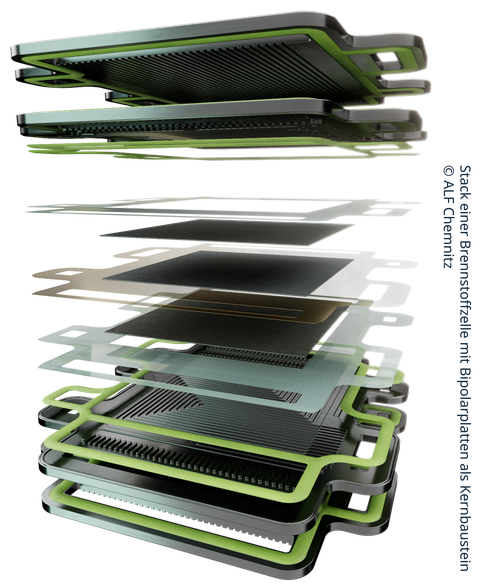

The BMWK's national hydrogen strategy forecasts a demand of over 25 TWh of H₂ by 2050. In order to avoid imports and make the energy supply independent, the production and costs of fuel cells (FC) and electrolysers (EC) must be reduced. Bipolar plates (BiP) are a major cost driver, accounting for 20-30% of total costs. Their production is particularly challenging due to their low sheet thickness (75-100 μm) and strict tolerances.

The project is investigating the bipolar plate (BiP) of a PEM low-temperature cell that can both generate energy from (green) hydrogen and split water. A new process consisting of hollow embossing rollers and laser treatment to reduce springback is being developed. The aim is continuous, precise production on an industrial scale with approx. 120 BiP/min, lower tool costs, less rework and good integration into roll-to-roll processes.