Research

Form and function are inextricably linked. Shaping manufacturing processes offer an enormous range of design possibilities and thus enable an enormous variety of functions. But things only get really interesting when these processes can also be combined and reliably planned.

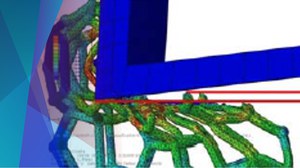

Our research therefore focuses on hybrid manufacturing processes, the simulation of manufacturing processes and planning methods.

Our research results primarily benefit energy and resource efficiency. After all, manufacturing is the second largest energy consumer after the steel industry. More energy-saving hybrid manufacturing processes and the economical use of resources through better planning methods can make a valuable contribution.

© freepik

© freepik

Our Mission

Shaping the future

Hundreds of thousands of industrial jobs in Germany are directly and indirectly linked to manufacturing. It is the backbone of the German economy. Without manufacturing technology, the world as it is today would not have been possible. But the world is facing new, unprecedented challenges.

Manufacturing technology companies account for 15 to 25 percent of the final energy demand in the manufacturing sector. This applies to individual processes such as primary and secondary forming, but also to machining, as well as to entire process chains made up of the individual steps. The future of manufacturing technology must be a sustainable one if it is to continue to serve social progress.

Better hybrid - process-oriented and digital

To enable companies to produce sustainably and conserve resources, we develop the manufacturing technologies needed for this purpose. We focus on hybrid processes and process chains. These offer enormous innovation potential, especially when the latest digital technologies are used. We research and develop the linking of individual technologies to form resource-saving process chains, as well as their demand-oriented design. The focus here is on shaping manufacturing processes such as sheet metal and solid forming, milling and turning.