Abteilung Modellbasierte Prozessplanung (MP)

Leiter der Abteilung: Dipl.-Ing. Sebastian Langula

Die Abteilung forscht und arbeitet an der Schnittstelle zwischen Fertigungstechnik, Digitalisierung und künstlicher Intelligenz. Unser Ziel ist es, die Fertigung der Zukunft nachhaltiger, flexibler und effizienter zu gestalten. Dabei legen wir den Fokus auf die Entwicklung innovativer Technologien, die sowohl die ökologischen als auch die ökonomischen Anforderungen moderner Produktionsprozesse erfüllen.

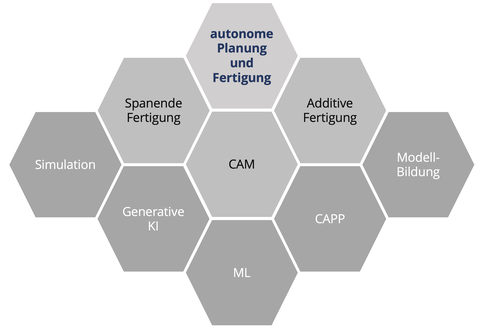

Die autonome Fertigungsplanung bildet das Herzstück unserer Abteilung. Unser Ziel ist es, intelligente Systeme zu entwickeln, die Produktionsprozesse selbstständig analysieren, optimieren und anpassen können. Im Fokus steht die Automatisierung der Prozessplanung, angefangen bei der Generierung von Werkzeugbahnen bis hin zur Steuerung komplexer Prozessketten. Darüber hinaus setzen wir auf die Integration moderner Technologien wie künstliche Intelligenz (KI) und maschinelles Lernen (ML), um datengetriebene Entscheidungen zu ermöglichen und adaptive Fertigungsprozesse zu realisieren. Eine besondere Herausforderung ist die Flexibilität in der Produktion, die durch dynamische Anpassungen von Fertigungs- und Logistiksystemen an wechselnde Anforderungen erreicht werden soll.

Nachhaltigkeit ist ein zentrales Anliegen unserer Arbeit. Wir entwickeln innovative Methoden und Technologien, die den Material- und Energieeinsatz optimieren und Abfälle minimieren. Hierbei legen wir großen Wert auf die Kombination spanender und additiver Verfahren, um die Vorteile beider Ansätze zu nutzen. Prozessoptimierungen zur Reduktion von Emissionen und Materialverlusten stehen ebenso im Mittelpunkt wie lebenszyklusorientierte Fertigungskonzepte, die durch innovative Prozessketten die Nachhaltigkeit in der Produktion fördern.

Ein weiterer Schwerpunkt unserer Forschung liegt auf flexiblen Fertigungsprozessketten. Ziel ist es, Produktionsprozesse so zu gestalten, dass sie robust und anpassungsfähig gegenüber variierenden Anforderungen sind. Dazu gehören hybride Fertigungsverfahren, die additive und subtraktive Technologien nahtlos miteinander verbinden. Zudem arbeiten wir an automatisierten Systemen zur Planung und Optimierung von Prozessketten, die eine dynamische Anpassung an unterschiedliche Produktionsszenarien ermöglichen. Ergänzt wird dies durch simulationsgestützte Ansätze, die eine präzise Vorhersage von Prozessverhalten und damit eine fundierte Entscheidungsgrundlage bieten.

Weiterführende Informationen und Übersichten erhalten Sie auch im Forschungsinformationssystem der TU Dresden.

Kontakt:

Leiter der Abteilung Modellbasierte Prozessplanung

NameDipl.-Ing. Sebastian Langula

Eine verschlüsselte E-Mail über das SecureMail-Portal versenden (nur für TUD-externe Personen).

Professur Formgebende Fertigungsverfahren

Professur Formgebende Fertigungsverfahren

Besucheradresse:

Zeuner-Bau, Raum 416 George-Bähr-Straße 3c

01069 Dresden

None