Forschungsgruppe Thermisches Fügen

Die Forschungsgruppe Thermischen Fügen der Professur für Fügetechnik und Montage an der Technischen Universität Dresden beschäftigt sich mit der Prozess- und Fügestellenanalyse, die in anwendungsorientierte Verfahrensentwicklungen münden. Der Fokus liegt in der Prozessbewertung und -überwachung, Prozessentwicklung und der Qualitätsbewertung von widerstandsgeschweißten und gelöteten Fügeverbindungen.

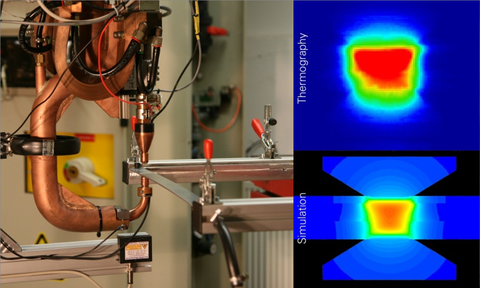

© Christoph Großmann

© Christoph Großmann

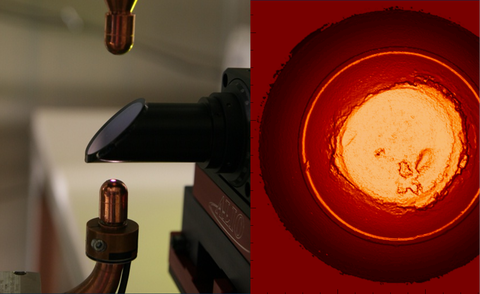

© Christian Mathiszik

Überblick der Forschungsaktivitäten

Schweißen und Löten mittels Widerstandserwärmung

- Prozessentwicklung von der Idee bis zum Protypen

- Prozessweiterentwicklungen für Mischbauweisen

- Erarbeiten von Prozessparameterfenstern und strategischen Verbesserungen von Prozesssicherheit und -handhabung

- Zerstörende Prüfungen zur sicheren Quantifizierung der Proben (Zug-, Druck-, Scher-, Schäl-, Kopfzug-, Torsions-Prüfung)

- Entwicklung neuer zerstörungsfreier Prüfverfahren

- Simulation von Ultraschall und Magnetfeldern zur Schweißlinsendetektion

- Simulation mittels eigener ANSYS Modelle

- Grundlagenuntersuchungen zu Prozessen in der Fügezone und insbesondere zu Prozessen an den Grenzflächen

Fügen, Trennen, Beschichten und Richten mittels Induktionserwärmung

- Induktives Schutzgasofenlöten

Schweißen und Löten mittels Vakuum- bzw. Schutzgasofen

- Effekte und Verhalten der Aluminiumoberfläche

- Lötbarkeitsbetrachtungen

Ansprechpartner

© Sven Ellger/TUD

© Sven Ellger/TUD

Wissenschaftlicher Mitarbeiter, SFI

NameHerr Dr.-Ing. Johannes Koal

Forschungsgruppenleiter Thermisches Fügen

Eine verschlüsselte E-Mail über das SecureMail-Portal versenden (nur für TUD-externe Personen).

Besuchsadresse:

Zeuner-Bau [ZEU], Raum 327D Helmholtzstraße 5

01069 Dresden

Deutschland