Research group Thermal Joining

The research group Thermal Joining of the Chair of Joining Technology and Assembly at the Technische Universität Dresden deals with process and joint analysis, resulting in application-oriented process developments. The focus lies on process evaluation and monitoring, process development and quality assessment of resistance welded, soldered and brazed joints.

© Christoph Großmann

© Christoph Großmann

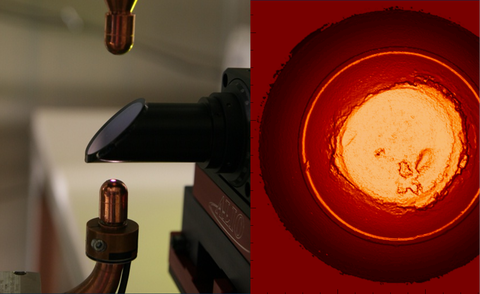

© Christian Mathiszik

Overview of research activities

Welding, soldering and brazing by means of resistance heating

- Process development from the idea to the prototype

- Joining-process developments for Multi-Material-Design

- Process parameter window identification and strategic improvements of process safety and handling

- Destructive testing for reliable quantification of specimens (tensile, compression, shear, peel, head tensile, torsion)

- Development of new non-destructive testing methods

- Ultrasonic and magnetic field simulation for weld detection

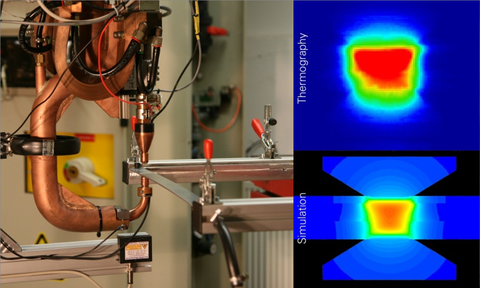

- Process simulation performed by own FEM-models in ANSYS

- Fundamental research on processes in the joining zone and in particular on processes at the interfaces

Joining, cutting, coating and straightening by means of induction heating

- Inductive inert gas furnace soldering and brazing

Welding, soldering and brazing by means of vacuum or inert gas furnace

- Effects and behavior of the aluminum surface

- Solderability considerations

Ansprechpartner

© Sven Ellger/TUD

© Sven Ellger/TUD

Scientist, IWE

NameMr Dr.-Ing. Johannes Koal

Research Group Leader of Thermal Joining

Send encrypted email via the SecureMail portal (for TUD external users only).

Visiting address:

Zeuner-Bau [ZEU], Room 327D Helmholtzstraße 5

01069 Dresden

Germany