Feb 28, 2025

Review: Exciting lectures in January and February

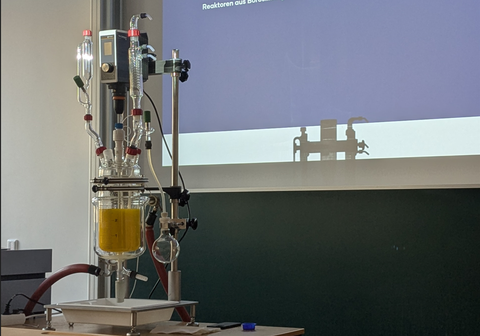

13/01/2025 - Pfaudler Normag Systems GmbH

On January 13, 2025, Manuel Stiebing from Pfaudler Normag Systems GmbH in Ilmenau gave students an insight into the extensive activities of his company as part of the lecture "Fundamentals of Chemical Process Engineering". Normag Systems GmbH specializes in the manufacture of apparatus and systems made of laboratory and process glass. In addition to manufacturing the glass apparatus, the company is also responsible for the design and layout of the systems, which are often used on a laboratory and pilot plant scale. Mr. Stiebing explained the special features of glass processing and the requirements for the design of systems used in various areas of the chemical industry. He also used interesting stories and experiences from his day-to-day work to explain to the students the challenges involved in handling and manufacturing large glass apparatus.

15/01/2025 - Linde Engineering

As part of the lecture series on Chemical Process Engineering at TU Dresden, Mr. Stefan Zimmermann from Linde Engineering Dresden gave a lecture on the role of process engineering and operating technology in plant design on 15 January 2025. The lecture covered both the historical development of Linde Engineering and current application examples from industry, in particular the plant design of LCO₂ plants and the application of new technologies such as PEM electrolysis.

The practical presentation of tasks and responsibilities - from process selection to engineering and commissioning - was particularly valuable for the process engineering students. The insights into real industrial projects gave the students a better understanding of the challenges and solutions in plant engineering. The lecture not only provided valuable theoretical impetus, but also highlighted career prospects in chemical process engineering. There was also the opportunity to gain deeper insights into the processes within the individual engineering phases by asking interesting questions.

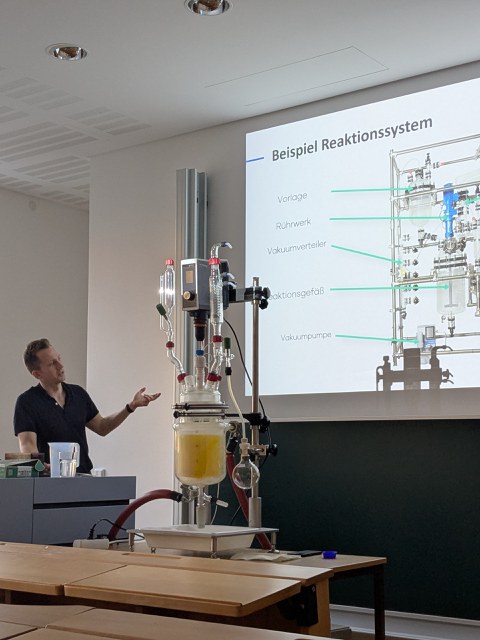

22/01/2025 - Fraunhofer IIS

On January 22, 2025, Dr. Göttl from Fraunhofer IIS gave an exciting insight into the future of process development in the lecture Plant Engineering. The focus was on the use of artificial intelligence (AI) for the automated creation of flow diagrams.

With the help of various machine learning methods, complex processes such as thermal separation can now be optimized more efficiently. Dr. Göttl explained this using a specific example: the AI determined the optimum number of columns for a separation task, the ideal position for feeding in raw materials (feed) and other crucial parameters.

The lecture took place online and aroused great interest among the students.

29/01/2025 - Laser Scanning Architecture

To give students an insight into professional life after graduation, an exciting guest lecture took place on 29/01/2025 as part of the plant project planning lecture. Mr. Johannes Rechenbach, Managing Director of Laser Scanning Architecture, presented impressive projects from the field of laser measurement technology.

With this technology, existing systems or buildings can be scanned in varying degrees of detail and then digitally mapped. Such as-built surveys make it possible, for example, to precisely record the flange sizes and positions of tanks and thus make the planning of pipelines more efficient. This method offers great potential to significantly reduce planning time for construction measures, especially for older systems whose documentation is often incomplete.

05/02/2025 - Siemens AG

The presentation "From Integrated Engineering to Integrated Operations - Maintenance and Repair Next Level", as part of the lecture on plant project planning, provided students with valuable insights into the digital transformation of industrial processes. Mr. Schongar and Mr. Mankel from Siemens AG presented innovative solutions, including the "Digital Twin" and the "COMOS Mobile Worker", which enable a seamless connection between the real and the digital world. These technologies optimize maintenance and servicing processes, increase efficiency and contribute to sustainability in the industry.

The lecture was particularly relevant for the process engineering students, as it presented practical use cases and modern digital tools that will play a key role in their future careers. They gained insights into the challenges and opportunities of digitalization, particularly in the chemical industry, and were able to understand how data-driven processes contribute to the optimization of production facilities. The lecture also provided a valuable opportunity to get in touch with experts from the industry and discuss current developments and career opportunities.

The students and the team from the Chair of Chemical Process Engineering would like to thank all the guest speakers for the fascinating insights into their everyday work and research.