Robust and cost-effective ceramic-based thermoelectric systems for industrial waste heat utilisation for a battery and mains-independent power supply (TEK system)

Teilprojekt: „Optimierte Wärmeübertrager für keramische TEG (TEG-WÜ)“

|

Editor: |

Dipl.-Ing. Roy Schwurack |

|

Duration: |

04/2016 to 11/2019 |

|

Funding institution: |

European Regional Development Fund (EFRE) and Free State of Saxony FKZ: 100234924 |

|

Project partners: |

Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) TU Dresden, Chair for Hydrogen and Nuclear Energy Technology (WKET) |

| Website | https://tu-dresden.de/ing/maschinenwesen/iet/wket/forschung/unsere-forschungsbereiche/innovative-lasertechnologien/te-k-system |

Project goals

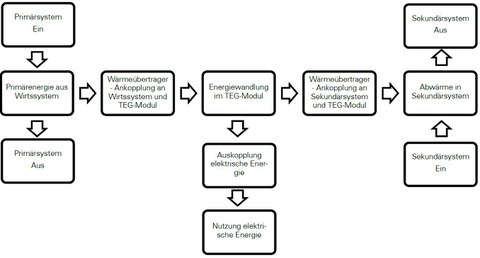

- Development and provision of a thermoelectric modular system that can be adapted to a wide range of applications

- Thermoelectric generator (TEG) based on ceramic materials with optimum system integration for use in the high temperature range

- Increasing the efficiency and economy of the overall system by means of adapted heat transfer systems for the thermal management of the thermo-electrical individual components

Expected advantages of the ceramic TEG modular system with optimised heat exchangers compared to conventional, commercially available TEG modules

- Ceramic materials allow operation in the high-temperature range and therefore make it possible to tap previously unused industrial waste heat sources for direct conversion into electrical energy

- Cost-effective and less environmentally harmful use of materials

- Thermal optimisation of the entire system by means of adapted heat exchangers delivers maximum efficiency and the best possible yield

- A heat exchanger TEG composite system that can be adapted to various industrial processes provides a robust, reliable, noiseless and vibration-free energy supply unit for very small consumers

- Autonomous operation of essential or safety-relevant components of a technical plant