Verfahrenstechnisches Praktikum

Das Verfahrenstechnische Praktikum wird in Kooperation mit den Professuren für thermische und chemische Verfahrenstechnik durchgeführt. Die Termine werden in der Informationsveranstaltung zum Semesterbeginn bekanntgegeben. Die Praktikumsunterlagen können im OPAL heruntergeladen werden: Praktikumsunterlagen 5. und 6. Semester.

Bitte beachten Sie auch die Hinweise zur Anfertigung des Praktikumsprotokolls!

Die Arbeitsgruppe Mechanische Verfahrenstechnik führt folgende Praktika durch:

Granulometrie

Das Granulometriepraktikum findet im Georg-Schumann-Bau A 119-121 statt. Die Partikelmessmethoden Mikroskopie, Siebung und Sedimentation werden angewendet und die Ergebnisse verglichen. Dabei werden die unterschiedlichen physikalischen Messprinzipien zur Bestimmung des Partikeldurchmessers bzw. der Partikelgrößenverteilung diskutiert.

Ansprechpartner: Dipl.-Ing. Fiala und André Kupka

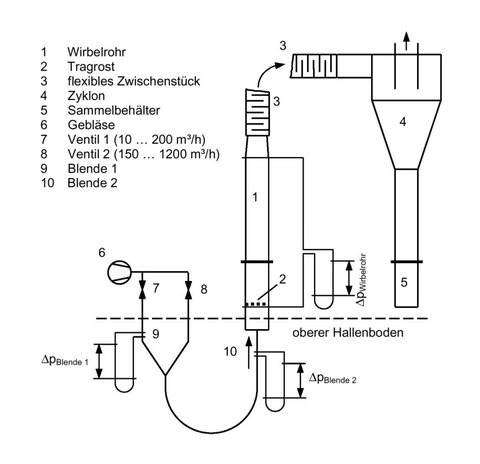

Wirbelschicht

Das Wirbelschichtpraktikum findet im Merkel-Bau statt. Eine Schüttung wird durch eine aufwärtsgerichtete Strömung in einen fluidisierten Zustand versetzt. Im Praktikum werden verschiedene Zustände angefahren und Kenngrößen der Wirbelschicht experimentell bestimmt.

Ansprechpartner: Dr.-Ing. Wessely

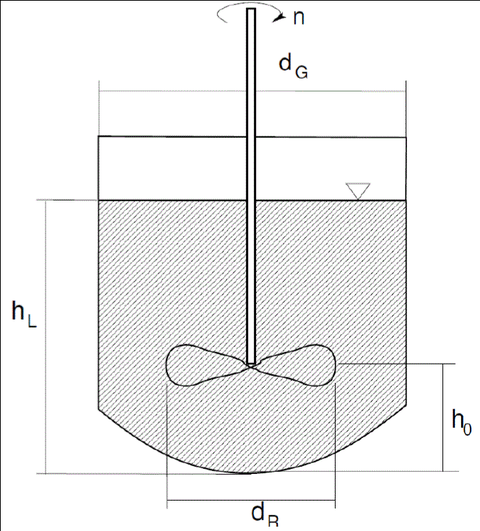

Standardrührwerk

Das Rührwerkspraktikum findet im Merkel-Bau statt. Im Mittelpunkt des Praktikums steht die Erkenntnis, dass neben den theoretischen Grundlagen auch experimentelle Untersuchungen im Labormaßstab notwendig sind, um einen Rührprozess optimal auslegen und fahren zu können. Die Kriterien, die zur Optimierung von Rührprozessen eingesetzt werden können, sollen im Rahmen der Versuche mit Modellstoffsystemen praktisch erprobt werden.

Ansprechpartner: Dr.-Ing. Wessely

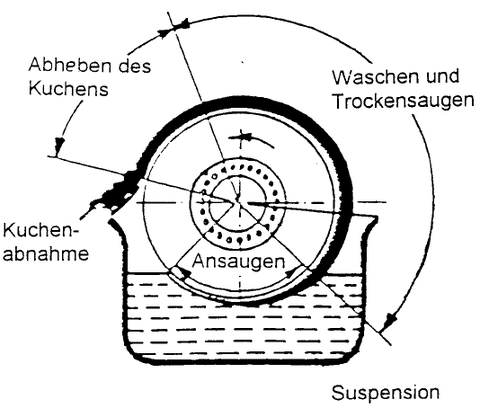

Filtration

Das Filtrationspraktikum findet im Merkel-Bau statt. Aus Versuchen mit einem Vakuumdrehzellenfilter und einer Handfilterplatte werden u.a. die Durchströmungswiderstände von Filtermittel (synthetisches Gewebe) und Filterkuchen (Kieselgur) sowie die Suspensionskennzahl bestimmt.

Ansprechpartner: Dr.-Ing. Wessely