Test plant Ulbricht-Kugeln

Measurement unit for synchronous determination of reflection and transmission of ceramics

(Ulbricht-Sphere)

Laser joining of ceramics is characterised by short process duration and enables a solid and sealed connection of the components by using defined and concentrated heating (higher temperatures T > 1000°C) as well as an adequate brazing solder. The optical properties (reflection, transmission and absorption) of the components determine the interaction between the Laser beam and the ceramics. Furthermore, the optical properties depend on the micro and surface structure as well as the size of the materials.

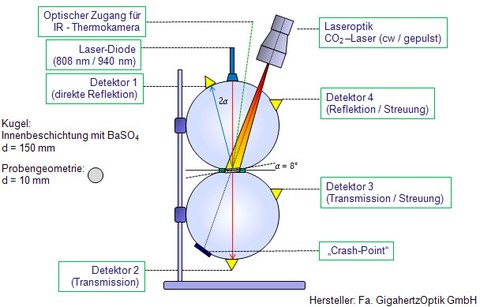

The measurement unit provides the means to synchronically determine the reflection and transmission of specially crafted ceramic tablets of various sizes. As a result, we are able to make statements about the absorption ability of the ceramic material at different wave lengths.

Material characteristics that occur during the wave lengths used in the laser joining process are especially interesting. Aiming for these characteristics, we calibrated the laser diode of the above mentioned measurement unit to operate at wave lengths of 808nm, respectively 940nm. The inner coating of the sphere is made from BaSO4, a good diffusely reflecting material. Directed and diffuse reflection can be measured by specifically positioned sensors in the upper part of the sphere. Furthermore, all prerequisites to measure transmission (directed and diffuse) are fulfilled by a small vent on the contact level, where the assay is placed, through which both spheres communicate.

The schematic representation can be described as follows: