Laser technologies

Table of contents

Contact

Head of the research area “Innovative Laser Technologies”

NameMs Dr.-Ing. Marion Herrmann

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Process Engineering and Enviromental Technology - Chair of Hydrogen and Nuclear Energy

Institute of Process Engineering and Enviromental Technology - Chair of Hydrogen and Nuclear Energy

Visiting address:

Walther-Pauer-Bau, PAU 214/1 George-Bähr-Straße 3b

01069 Dresden

© WKET

© WKET

Research Associate

NameMs Dr.-Ing. Anne-Maria Reinecke

Head of high-power laser laboratory

Send encrypted email via the SecureMail portal (for TUD external users only).

Institute of Process Engineering and Enviromental Technology - Chair of Hydrogen and Nuclear Energy

Institute of Process Engineering and Enviromental Technology - Chair of Hydrogen and Nuclear Energy

Visitor Address:

Mollier-Bau, MOL 312 George-Bähr-Str. 3

01069 Dresden

None

Innovative energy technologies in many cases require processes at temperatures above 800 °C. This places special demands on the materials and components to be used. Therefore, for more than 15 years, the scientists of our teaching and research area Research Group have been developing and modifying laser technologies that enable the use of different materials under the conditions of high temperature and special environmental conditions. In each case, laser-based technologies for joining, coatings and surface structuring are developed and applied for this purpose.

We are active in the following areas:

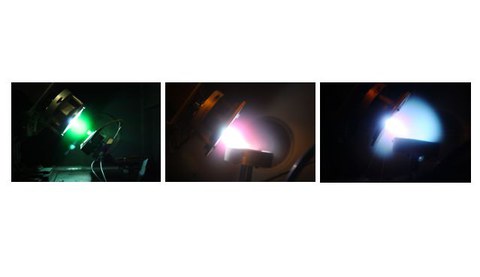

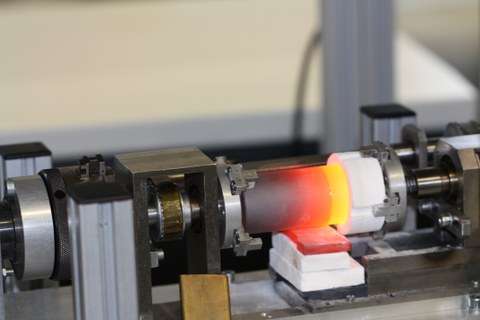

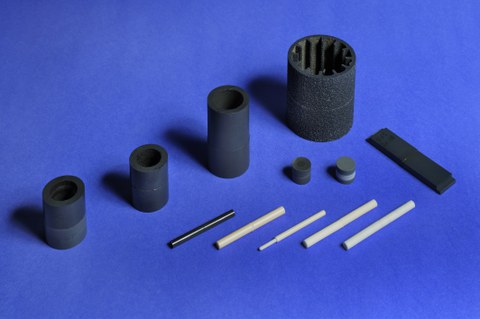

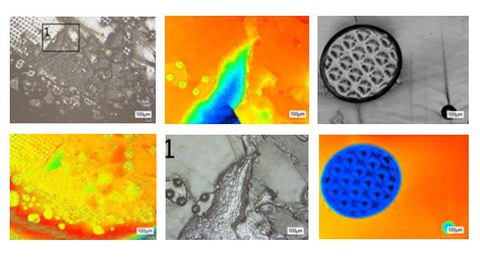

- Development and testing of laser-based soldering technologies for high-temperature resistant joining of ceramic-to-ceramic or ceramic-to-metal joints. The special features of the process, local energy input and short process times are used to advantage.

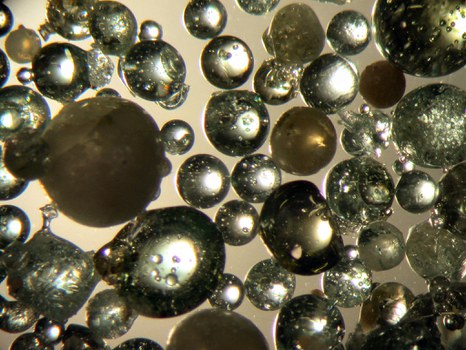

- Development of high-temperature brazing alloys for use under special environmental conditions. The development includes the group of metallic active solders as well as glass-ceramic solders.

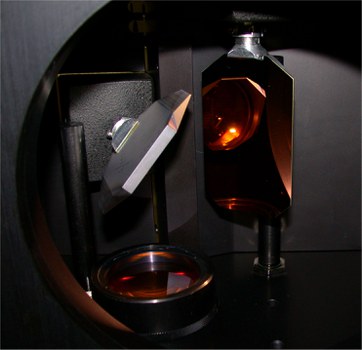

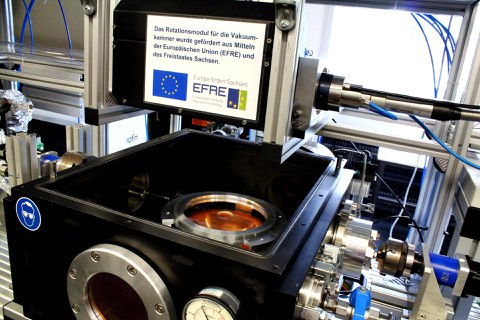

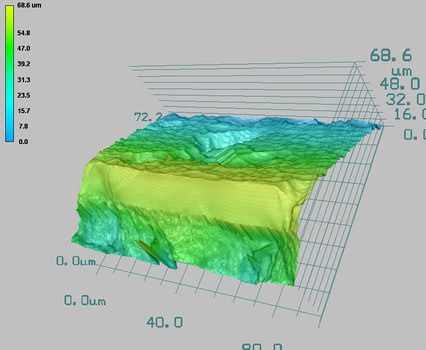

- Development of a laser-assisted coating technology (PLD process) for producing ultra-dense, chemically precisely defined ceramic coatings. These can be used, for example, for the long-term stable, safe confinement of radioactive fission products as well as for the protection of surfaces against corrosion and abrasion.

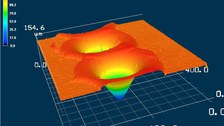

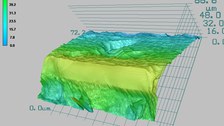

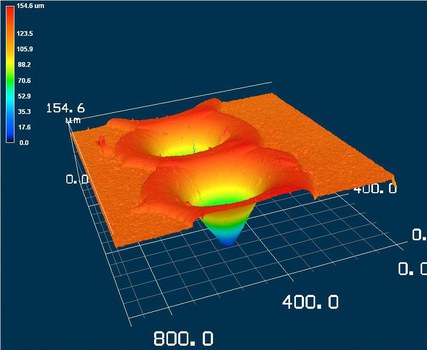

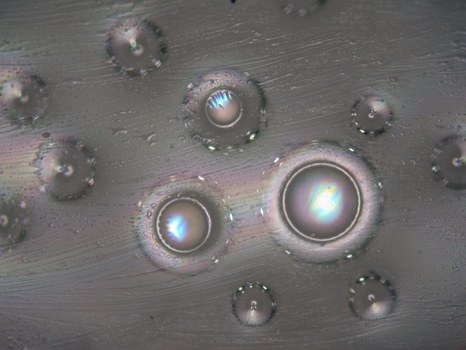

- Laser-based structuring of ceramic surfaces to increase the specific surface area and/or to adjust special surface properties.

Another focus of our work is the development of resource-saving technologies for the dismantling of nuclear power plants. Laser-based technologies can make an important contribution to this, and we are establishing these personnel- and resource-saving processes in practice as efficient alternatives to conventional methods.

Our main areas of work are:

- Development and testing of innovative procedures for laser-based decontamination of radioactively or chemically-toxically contaminated surfaces. These methods represent a personnel- and resource-saving alternative to conventional, mechanical decontamination technologies.

- Development of a method for laser-based sampling in concrete boreholes for in-situ analysis.

- Laser-based cleaning of various surfaces to remove oxide layers, for example.

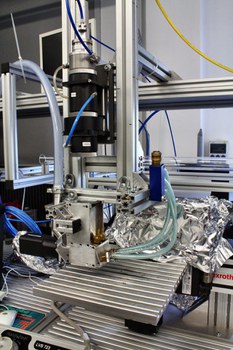

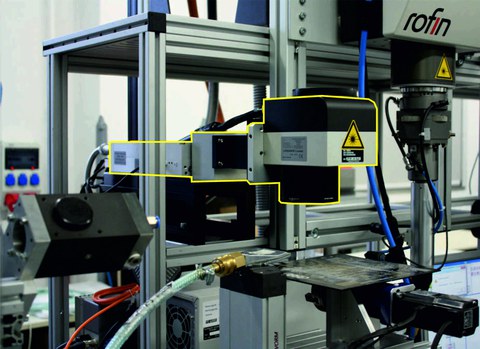

The research group has access to a state-of-the-art laboratory equipped with powerful lasers of different wavelengths and working modes as well as the corresponding peripheral equipment for its research work.

Student research projects

Current tasks of the Chair of Hydrogen and Nuclear Energy Technology can be found here.

Projects

Weitere Informationen finden Sie imForschungsinformationssystem der TU Dresden.

Publications and patents

Experimental plants

Cooperation partners of research area "Lasertechnologies"

TU Freiberg, Institut für Wärmetechnik und Thermodynamik

Institut für Wärmetechnik und Thermodynamik (IWTT)

TU Freiberg, Institut für Keramik, Glas- und Baustofftechnik

Institut für Keramik, Glas- und Baustofftechnik

Industrieanlagen Betriebsgesellschaft mbH (IABG mbH)

IABG

Wiederaufarbeitungsanlage Karlsruhe, Rückbau- und Entsorgungs-GmbH

WAK GmbH

Helmholtz-Zentrum Dresden-Rossendorf, Inst. Experimentelle Thermofluiddynamik

HZDR Experimentelle Thermofluiddynamik

Helmholtz-Zentrum Dresden-Rossendorf, Institut für Fluiddynamik

HZDR Institut Fluiddynamik

Rheinisch-Westfälische Technische Hochschule Aachen , Lehrstuhl für Reaktorsicherheit und -technik

RWTH LRST

KIT Karlsruhe, Institut für Angewandte Materialien

IAM

Fraunhofer Institut für keramische Systeme, Abteilung: Nitridkeramik und elektrisch funktionelle Strukturkeramik Dresden

IKTS Nitrid- und elektrisch funktionelle Strukturkeramik

Fraunhofer Institut für Keramische Systeme, Abteilung: Fügetechnik und AVT Dresden

IKTS Fügetechnik und AVT

Max-Planck-Institut für Chemische Physik fester Stoffe Dresden

MPI für Chemische Physik fester Stoffe

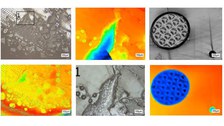

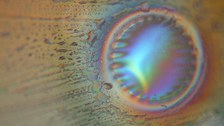

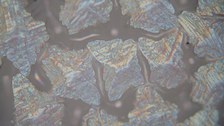

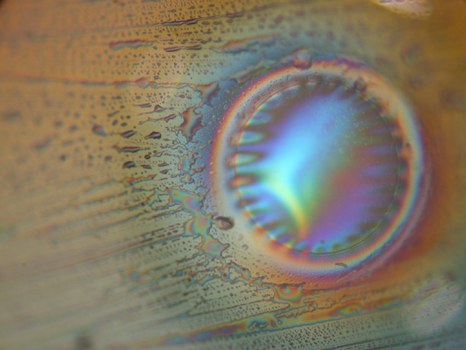

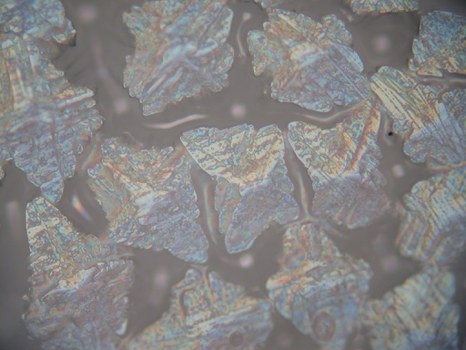

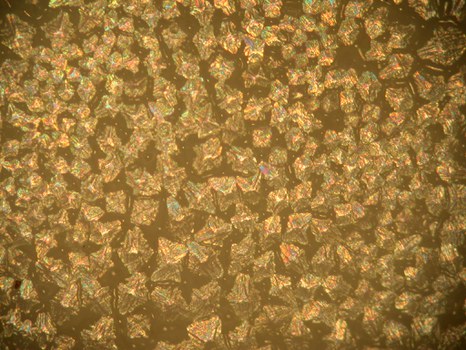

Picture gallery

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Carsten Giersberg

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET

© Redaktion WKET