„Experimental and theoretical study of the decay heat removal from spent fuel in evaporating wet storage“

Research project SINABEL "Safety of spent fuel pools: Experimental analysis, modeling and validation of system and CFD codes„ within the framework of the BMBF funding concept "Basic Energy Research 2020+"

Sub-Project „Experimental and theoretical study of the decay heat removal from spent fuel in evaporating wet storage“

(Support code: 02NUK027A)

| Project manager: | Prof. Dr.-Ing. habil. Wolfgang Lippmann |

| Assistant project manager: | Dr.-Ing. Christoph Schuster |

| Contributor: | Dipl.–Ing. Patrick Zedler |

| Duration: |

10/2013 – 09/2019 |

| Funding: | BMBF |

| Funding code: | 02NUK027A |

SINABEL 2013 – 2017

At the Chair of Hydrogen and Nuclear Energy of the TU Dresden the ALADIN test facility was built as part of the joint project SINABEL. ALADIN is utilized to simulate incident scenarios that can occur in real spent fuel pools. The examined scenarios are evaporation, water blockage and air cooling.

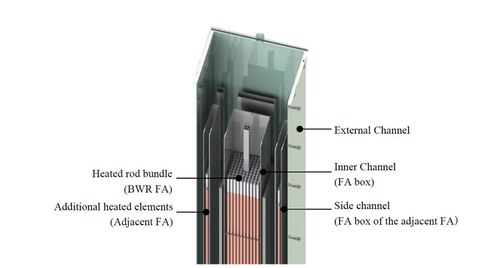

In order to investigate the thermal loads of a boiling water reactor fuel assembly during an accident in the spent fuel pool experimentally, the fuel assembly and its surroundings were constructed on a scale of 1:1. This ensures the fluid mechanical and thermal comparability to real spent fuel pools. The basic structure of the test facility is shown in figure 1.

Until the end of the first project phase (09/2017), experiments with different heating power and distances between the fuel element and the edge and corner elements were carried out.

In addition, the ALADIN test facility was modeled with the integral code ATHLET and comparisons of experimental data and ATHLET simulations had been performed.

Extension 2017 – 2019

The ALADIN test facility is going to be equipped with additional appliances for the analysis of cross-overflow at the fuel assembly head and the investigation of the influence of spray cooling of the fuel assembly.

For influencing the air flow at the ALADIN outlet specifically, a flow channel is planned. The air movement there has an impact on whether cold air in counterflow to hot gases from the rod bundle can reach the bars or gaps between the fuel assemblies and thus producing an additional cooling effect. The overflow area is instrumented with a grid of thermocouples. A transparent design allows the visualization of the flow field.

The establishment of a spray cooling system for the investigation of the temperature field in the rod bundle with the specific spraying of water droplets is planned as a subsequent experiment.

The pre-existing ATHLET Model for ALADIN will be adapted to simulate spray cooling.