gamma-titanium aluminides alloys

Embrittlement of a gamma-titanium-aluminides due to a high temperature oxidation - mechanism and measures to avoid it

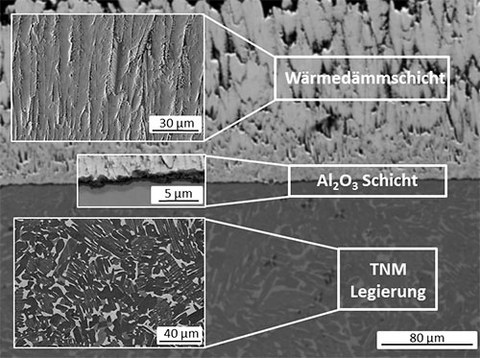

The goal of the joint project is to undertake a fundamental investigation of the influence of the thermal loads during processing steps such as pre-oxidation and deposition of the thermal protection layer as well as the subsequent high temperature outward diffusion on the microstructure and properties in the interface in order to provide a solution route for the suppression of interface embrittlement. In order to reduce the interface damage the substrate material must be protected by an appropriate oxygen barrier that has a low oxygen solubility and a small oxygen diffusion co-efficient in combination with an excellent oxidation behaviour and a good chemical compatibility with the substrate material. Currently, investigations are looking at and optimising with regard to embrittlement, for example, a material system composed of a TNM-B alloy (substrate), an aluminium oxide layer (oxidation protection and adhesion layer) and a ceramic thermal protection layer (high temperature protection) (figure 1).

Figure 1: REM-BSE recording of a material system composed of a TNM-B alloy with Al2O3 layer and ceramic thermal protection layer

Contact persons

Prof. Dr.-Ing. Christoph Leyens

Project partner

-

German Aerospace Center (DLR), Köln

-

DECHEMA-Forschungsinstitut (DFI), Frankfurt/Main