Cast part quality

Quantitative assessment of a thick walled cast part based on the thermal analysis of the solidification process, and associated microstructure and mechanical characterisation

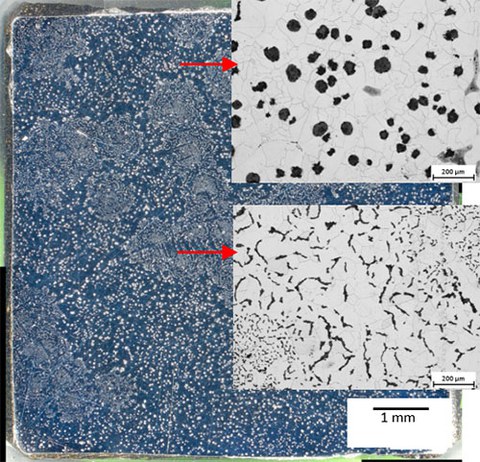

At the centre of the joint project with Heger Guss GmbH and Heraeus Elektro-Nite GmbH & Co. KG is the development of a signalling system for the simple quality control of cast parts – formation and distribution of graphite (figure 1) – in ductile graphite iron production for wind turbines. For this thermodynamic data will be taken during the solidification of defined melts of large cast parts as well as for the same melts in small Quick Cup vessels, and directly correlated with the microstructural and mechanical properties. The developed machine should record and assess data about the melt, like a finger print, so that the users during the production can make immediate conclusions about the future quality of the cast part and make, if necessary, changes to the melt before it is cast.

Figure 1: Different microstructure formations in ferrite cast iron

Contact persons

Project partner

- Heger Guss GmbH

- Heraeus Elektro-Nite GmbH & Co. KG