May 04, 2022

Lightweight design for the Circular Enonomy - Resource-efficient vehicle structures with functionalized composite hollow profiles

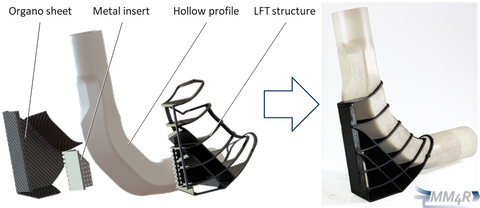

Generic FuPro structure: Design (left) and manufactured part (right).

Start of the project „Recycling-ready multi-material design for lightweight structures“ (MM4R)

Nine project partners, including the TU Dresden Institute of Lightweight Engineering and Polymer Technology (ILK), aim to replace the aluminium/magnesium vehicle cross car beams with functionalized composite hollow profiles. Under the leadership of Porsche the FuPro technology is prepared for series production taking special care of the recyclability and environmentally impact of the new component design.

Lightweight components for vehicles are one of the key factors for resource-efficient mobility. Over the last few years, hybrid component design has become increasingly important since it synergistically combines material, design and functional lightweight aspects. Compared to monolithic aluminium or magnesium structures, the use of fibre-reinforced thermoplastics in combination with local metallic load introduction elements can reduce the environmental impact throughout the entire life cycle of the component. Especially the combination of thermoplastic composite hollow profiles, organo sheets and injection moulding compounds (FuPro design) is predestined for the substitution of the energy-intensive aluminium/magnesium design. With a single material system consisting of short, long and continuous fibre-reinforced semi-finished products, engineers are at the same time given maximum design freedom. A major advantage of the FuPro design is its recyclability. At the same time, the design has considerable economic potential due to its integral character. However, in order to fully exploit this, manufacturing technologies still need to be optimized along the process chain in terms of energy consumption and process time. In addition, the previously necessary chemical adhesion promoters for bonding the plastic components and metal inserts are to be replaced by laser structuring of the surfaces in order to ensure recyclable material flows that are free of contamination as far as possible in the recycling process. Finally, the thermoplastic design is also intended to enable a waste-free part manufacturing by reprocessing cut-offs. These technological goals of the MM4R project are meant to facilitate the transition of the FuPro design process into volume production.

Environmental and social aspects are becoming increasingly important in the research, development and application of structural components. Therefore, in MM4R the technological work is enhanced by a Life Cycle Sustainability Assessment (LCSA). Such a comprehensive assessment of the environmental impact of hybrid lightweight structures poses multiple modelling and accounting challenges, such as the primary data collection for the production of the fibrous semi-finished products. The MM4R project is the first to provide holistic assessment techniques specific to the FuPro design and its manufacturing technologies. Furthermore, the integration of the LCSA method into the development process will enable engineers to directly consider ecological and economic aspects as well as possible social hotspots in the design phase and to actually create sustainable FuPro products from scratch.

Project MM4R: „Recycling-ready multi-material design for lightweight structures“

Funding

Duration

01.12.2021 – 30.11.2024

Project partnership with

Consortium leadership: Dr.-Ing. h. c. F. Porsche AG

ARBURG GmbH + Co. KG

AUMO GmbH

EKF Automation GmbH

Fraunhofer Institute for Material and Beam Technology (IWS)

FRIMO GmbH

Institute of Lightweight Engineering and Polymer Technology (ILK) of the TU Dresden

Institute of Sustainability in Civil Engineering (INaB) of the RWTH Aachen

Motherson - SMP Deutschland GmbH

Project management at ILK

Prof. Dr.-Ing. habil. Dipl.-Math. Maik Gude, Chair of Lightweight Design and Structural Assessment

Contact at ILK

Dipl.-Ing. Alexander Liebsch, Expert Group Joining technologies, Tel.: +49 (0)351 463-42504,

Dr.-Ing. Robert Kupfer, Expert Group Neutral Lightweight Engineering (research group leader), Tel. +49 (0)351 463-38749,

Futher Informations

Webpage of the project MM4R

Webpage of the pre-project FuPro

Expert Group Neutral Ligweight Engineering at ILK